Good relations

For BA Vidro the scale of their operation meant that reliability and customer service were both high on their list of considerations when they began looking for a new printing partner.

During the test phase, BA Vidro representatives spoke with other Domino’s customers to learn more about the level of service our company could give.

“We were pleased with the customer support provided by our previous coding technology supplier, so when the time came to change our service provider we focused a lot on this aspect.”Joaquim Campos, Maintenance Manager at BA Vidro.

“We were pleased with the customer support provided by our previous coding technology supplier, so when the time came to change our service provider we focused a lot on this aspect.”

Joaquim Campos, Maintenance Manager at BA Vidro.

“We are very pleased

with the reliability of the printers and with the level of service provided, but what impressed us the most about Domino was how they demonstrated from the beginning that they are very keen on forging a relationship with us. We can honestly say it’s been a very successful one.”

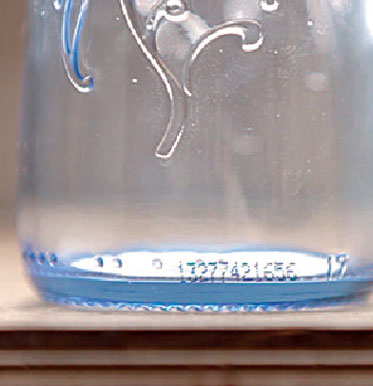

Working closely with Domino, the organization began a test phase with the A420i inkjet system, the precursor to the connected Ax350i. BA Vidro chose the A-Serie inkjet because it offered low ink costs, minimal operation and could be easily integrated into their existing production facilities. Our A-series, the forebear of the current Ax-Series Continuous Inkjet, had proven reliability, which was also essential given the scale of their operation.

Within three months, BA Vidro was ready to sign contracts with Domino, rolling out our Continous Inkjet printers across their entire production line, replacing the 14 other systems they were running at the time.

The result? After 18 months of use, they’d experienced zero production malfunctions.