If you're in an office building, chances are that you're no more than a few feet from a pane of tempered glass. Even if you're working from home, chances are there are a few panes by the entrance of your house. It’s one of those materials that’s in near-constant demand.

As a manufacturer, the speed and accuracy with which you can add safety codes, logos and other branding elements to your glass is essential for satisfied clients and healthy profit margins. So what’s the best way to add coding and marking to glass?

Is market demand for tempered glass on the rise?

What sort of shape is the glass industry in? Well, in terms of economic sentiment and market buoyancy, the construction sector serves as a decent barometer and allows glass producers to anticipate future demand.

According to Mordor Intelligence, the Tempered Glass Market is expected to grow over 6% during the forecast period of 2021 to 2026. This growth is despite headwinds including the pandemic lockdowns and unpredictable demand in vehicle glasses.

However, these issues should be offset by increased demand from the construction industry and electronics industry. The latter came boosted demand for laptops and computers as workers began to work from home, stimulating growth in screen monitor glass.

This data signifies that suppliers of tempered glass materials will need to look at ways to either strengthen their market share, or better manage existing processes to maximize efficiencies.

What codes are needed for tempered glass?

Which industrial printing technology is used in the tempered glass industry? Here are the types codes that find their way onto panes of glass:

- Company branding - (Logo and brand name)

- Batch numbers

- Traceability codes

- EN marks

- BSI kitemarks (in the UK)

The vast majority of glass used in construction and transport require some degree of coding or marking. Some clients are beginning to request the omission of safety marks, yet this betrays regulation and carries the risk of fines. In short: never omit safety marks.

What coding technology etches those codes? Lasers.

Marking glass while preserving the integrity of the material can be a big challenge. Traditional ink methods result in low-contrast marks, while chemical etching alternatives are time-consuming and involve consumable costs which can build up over time. In addition, if the wrong ink is specified this may result in fading or rubbing off over the lifetime of the glass product.

Laser marking however is a globally proven option for adding high-contrast, permanent marks that are unaffected by the toughening process. The ability to print variable data at high speeds is well suited to reducing lead times in busy production environments, while the consumables-free nature of laser coding translates into low operating costs and minimal downtime long term. In fact a high-quality laser coder will run 24/7 with exceptional efficiency.

>> Find out why Domino’s D-Series of laser coders are popular for glass coding

Beyond the code...

It’s not just the direct application of coding that Domino has supported glass manufacturers with. Domino’s specialist project engineering teams have also created a mobile glass coding table that replaces the need for stickers or sand blasting on your production line. It’s height adjustable, fitted with industry-grade rollers and can be placed at the side of any existing float or roller breakout table. It enables you to move glass with ease, a manual alternative for offline production situations.

Want to know more?

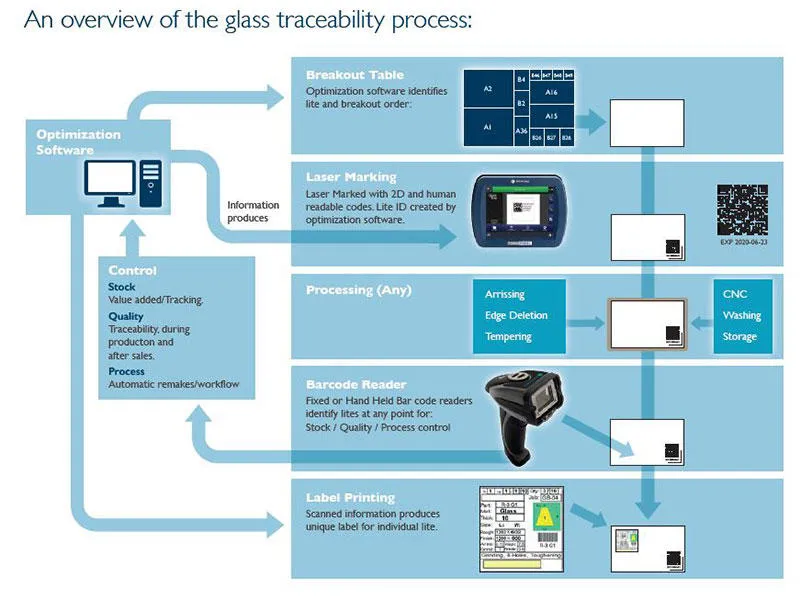

Of course, the traceability of your glass is business-critical too. Domino offers specialist software that enables you to keep tabs of every item both during and post-production. Integrating seamlessly with your order entry software and the laser coder, Domino’s traceability solution provides a data record for each sheet/batch that you produce with variable human and machine-readable codes placed consistently on the glass. It makes it easy to match the right sheet to the right frame and track the location of completed batches across your production site and beyond.

Want to learn more about the Domino D-Series laser and how it can improve your tempered glass traceability?