Pressure Sensitive Labels (or "PSL" for short) are what you see on food, beverage and household products when you roam the grocery aisles today. These labels are as much about the brand itself as they are informational. So what makes them different from any of the other labels? PSL are widely used for labeling purposes due to their low cost and premium designs. These labels can make any product stand out and they offer immense customization possibilities too.

The PSL allows for applications that other marking and coding technologies either cannot handle or require extra processing steps in order to enable another printing technology. PSL can be either a solid back color, typically white, allowing for bold contrasting print for barcodes and text of tiny to large size. PSL can have a uniform color and still allow for bold printing, which is regularly used in industries that wish to make quick visual notice of special stock or stock age at a distance. The PSL can be fully color printed offline and used for advanced marketing or product information. A combination of partial preprint and online printing can yield the best of both worlds, by allowing color for marketing, while giving the necessary sharp black on white contrast for scanning. The PSL is a very versatile method to use for marking and coding on primary to tertiary (pallet) labeling, since the label provides the solid substrate and ability to attach to most any product surface.

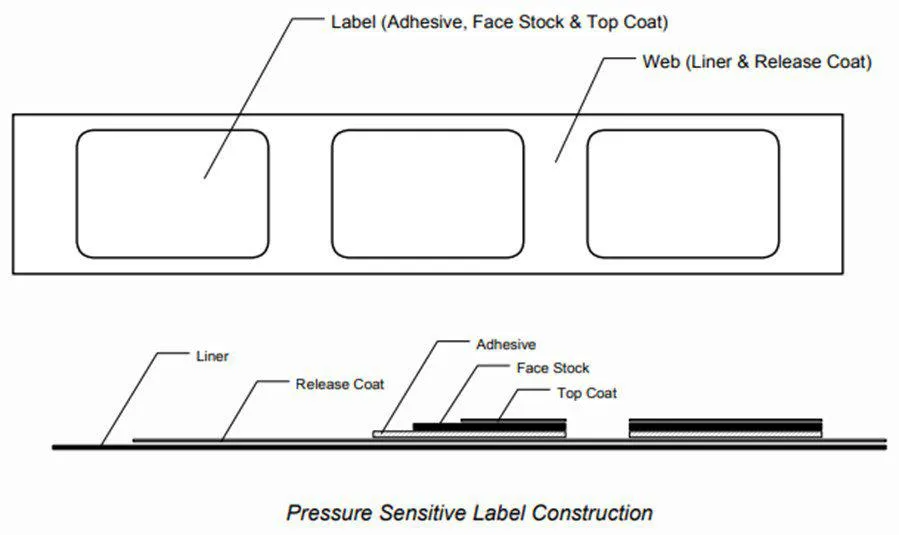

The PSL "Sandwich"

Pressure sensitive labels are constructed as a sandwich of several layers:

• Top Coat

• Face Stock

• Adhesive

• Release Coat

• Liner

Top Coat

The top coat is a coating or lamination applied over the face stock, to provide physical protection from abrasion or to enhance some other property of the label. Top coats can be used to improve adhesion or legibility of secondary imprints, typically used for date or lot coding. Special UV sensitive varnishes or films can be used to assist with label on product detection, during the labeling process.

Face Stock

Although the most common face stock material is paper, many other materials are used including plastic films, foils, fabrics and laminates

Adhesive

The adhesive is the glue that sticks the face stock to the product. There are a wide variety of adhesive formulations available. Adhesive selection is generally based on the application:

- Permanent or Removable

- Product Surface Material – Paper, Plastic, Metal, etc.

- Label Application Temperature

- Product Storage Temperature

- Product Surface Texture - Smooth or Rough

- Wet or Dry Environment

Usually Rubber-based or Acrylic-based.

Rubber Adhesives

Rubber adhesives have a strong initial tack, which means they grab onto surfaces and adhere tightly very quickly.

Rubber adhesives often have a yellow tint to them, which can show through a label.

Rubber adhesives work well at most normal room temperatures, but they begin to lose their stickiness at higher temperatures above 160 degrees Fahrenheit (70 degrees Celsius). They also aren't very resistant to ultraviolet (UV) light, so they may not be the best choice if you plan to apply your labels to anything that sits outside in the sunlight.

Labels that use a rubber adhesive are usually water-resistant, but they don't hold up well to chemical solvents.

Acrylic Adhesives

Acrylic-based adhesive pressure sensitive labels are available in permanent and removable varieties. While acrylic adhesive labels are generally more expensive than rubber-based adhesive ones are, acrylics have several advantages that make them worth the extra cost to some companies.

Acrylic adhesives are clear and resistant to sunlight, making them a good choice for transparent labels and labels that come into contact with direct sunlight. Acrylics are more heat-resistant than rubber adhesives as well.

Pressure sensitive labels that use acrylic adhesives are generally stronger than rubber-based labels, and acrylics also adhere better to a wider variety of materials and curved surfaces than rubber adhesives do.

Release Coat

The release coat is a coating applied to the top surface if the liner. The release coat is designed to resist the adhesive, allowing the face stock and adhesive to peel away from the liner. Usually Silicone.

Liner

The liner is the backing paper that makes up the web of a roll of labels.

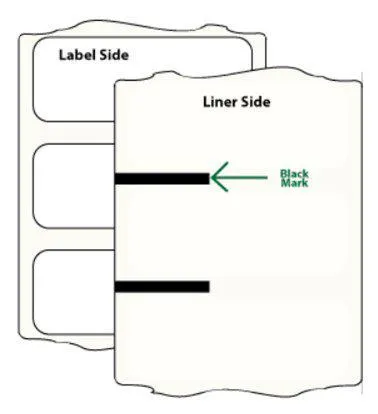

There are many different liner types, such as paper, kraft, clear poly, etc. Liners that have clear labels will often need a registry (black) mark in order to signal the printer for the end of one label and the another.

Factors to consider when considering PSLs

Label Size

Label size is defined based on the label’s orientation on the web as seen below. Width across the liner and Length in the unwinding direction. ALWAYS measure it by width vs length on the roll, never the product itself.

Label Edges

The label edges should have a radius for auto apply systems. A greater amount of radius will help in the following areas:

- Allows for better peeling at the peel blade of the printer or label applicator

- Reduces the chance for flagging of the label once on the surface. This is when the label is not tacked in the corners, and with the stress that a 90 degree angle has on the label surface tension, the edge is likely to lift up

- Better diecutting during the printing press (converting) process. Square edges are more prone to issues with the waste matrix

Label Thickness (Caliper)

Standard label thickness is typically around 0.002" to 0.005" for the label alone. If the label has other features, such as piggyback labels (see below) or booklets, there can be a requirement to make some changes on the labeling system to accommodate them. Such things include increased roller diameters for dancer and idler arms, to prevent pre-peeling of the labels before they reach the dispensing point.

There is a maximum thickness that cannot be exceeded and that will vary by manufacturer. If the label caliper is greater than 0.010", this should be checked with the manufacturer to confirm compatibility.

Temperature & Humidity

Certain label adhesives can be negatively impacted by both high and low temperatures. Acrylic adhesives can be a good choice for labels that will be exposed to higher temperatures. Adhesives can also have a minimum application temperature, so you need to consider the conditions of your applicating environment as well.

Surface

What your labels will be placed on plays a big role in how well they can adhere to your packaging. Some surface materials provide better adhesion than others, which can depend on a couple of factors.

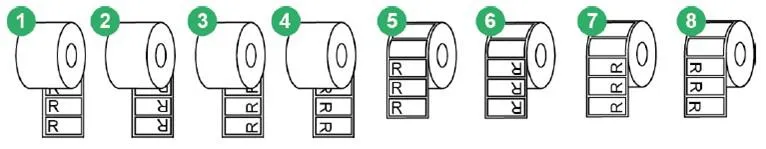

Label Copy Positions

The orientation of the copy on a label is an important consideration when specifying and automatic labeling system. The copy position chart below provides a standardized way to describe the eight possible combinations. For automatic labeling applications, labels are typically wound out.

Where to begin?

Choosing the right label involves weighing a variety of factors, all of which can play an important role when making sure your labels adhere properly to your packaging. It can be difficult to find the right label solution that balances both performance needs and budgetary limitations, especially without any background in label Printing.

Domino is of course known for our technology but did you know we also offer labels for our print-and-apply labeling solutions? We have dedicated in-house label experts to work with you to review what factors may affect your labels, as well as any other issues that may impact their performance.

Let's start by connecting! Reach out to Domino North America at solutions@domino-na.com.