Since the technology was introduced in the 1960's, continuous inkjet printing (CIJ) remains one of the most commonly-used coding technologies in manufacturing today. With the focus on traceability across the supply chain, achieving accurate, reliable and repeatable codes has never been more essential. Welcome to the science behind the perfect drop.

History of the Modern Continuous Ink Jet Printer

Modern continuous inkjet (CIJ) printers can trace their lineage to the early works of Belgian physicist Joseph Plateau and English physicist Lord Rayleigh (John William Strutt). Plateau was the first to publish in 1865 establishing the relationship of jet diameter to drop size. Lord Rayleigh built upon Plateau’s foundation to publish the series Instability of Jets in 1878 where he was the first to recognize that break-up of liquid jets is independent of how the jet is formed. Rayleigh went on to conduct experiments using acoustic energy to form uniform drops.

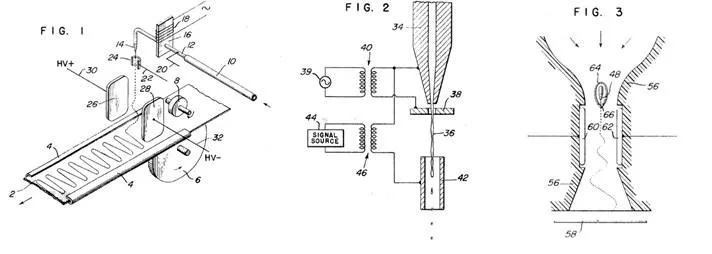

Like other scientific innovations, it would be several decades before these revelations would be used in practical applications. In the 1960’s, Dr. Richard Sweet at the Stanford Research Institute made further progress in the field. He patented a method which deflected individual droplets of ink in a continuous stream in what he termed the Inkjet Oscillograph. Thus, the beginning of the CIJ printing was established.

Image: Inkjet Oscillograph, US Patent 3,596,275 Filed March 25, 1964

Developing the Perfect Drop

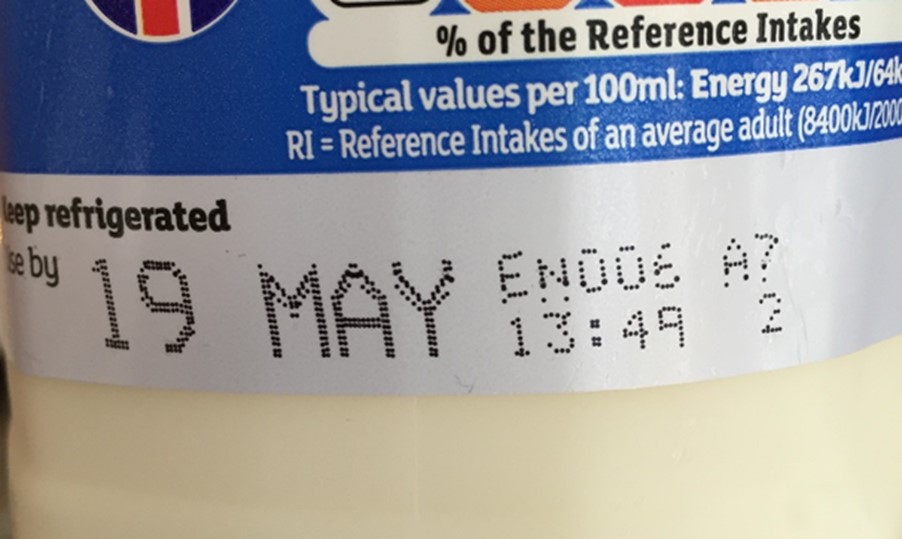

Print quality starts and ends with the ink drop. If the drops are not round, do not maintain a consistent pattern, or have inconsistent distance between drops, legibility will suffer.

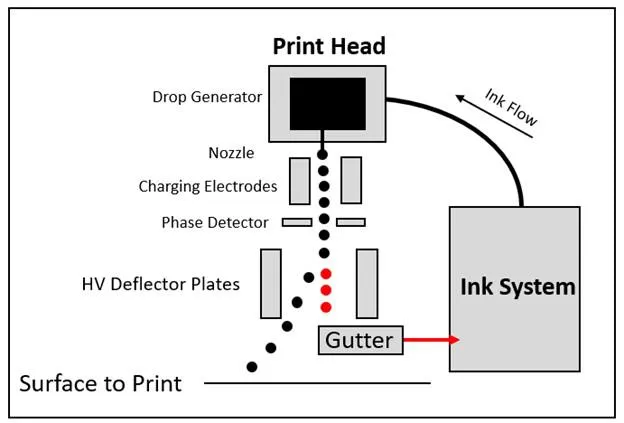

Dr. Sweet proved droplets of uniform size and spacing could be produced from an ink stream when a pressure wave was applied to an orifice. This pressure wave is developed when piezo crystals within the drop generator are excited by an electrical stimulus. The Charging Electrodes selectively charge the ink droplets which then travel through an electrostatic field where they are deflected based on the amount of charge they contain. Uncharged ink droplets are caught in the gutter and returned to the ink system.

The CIJ method is an economical printing option that offer can offer advantages over other industrial printing technologies, however there can be a drawback—Satellite drops.

Satellite drops are unwanted, secondary ink droplets that are common in inkjet printers. These satellite drops, depending on ambient conditions and the specific ink characteristics, will either rejoin a primary charged droplet or will be applied to the material being printed. While the first is acceptable, the second can be problematic both to print quality and increased printer maintenance.

When factors that normally create satellites are accounted for, they can be controlled, and thus the satellites may be reduced or even removed. The best way to eliminate the creation of satellite droplets is to ensure the ink stream is vibrated at the optimum break-up frequency with the correct voltage amplitude.

This amplitude signal, called the Modulation Voltage, controls the break-up of the ink when it excites the crystals in the Drop Generator. The Drop Generator breaks-up the ink stream as it goes into the nozzle. A good way to picture how this works is to think of holding a garden hose as water is flowing through it and tapping it from the side with your hand. The tapping of the hose disrupts the water stream; the harder you tap it, the more it changes the water stream from the nozzle. (You’re not concerned about satellite drops as you water the lawn.)

During printer operation, temperature and ink viscosity will fluctuate. These normal variations will require the modulation voltage to increase or decrease to maintain the break-up and charging of the ink droplets within the charge electrodes channel.

There is range of voltages (a.k.a Modulation Window) that will break-up the stream satisfactorily, but the peak voltage ensures the PERFECT Drop —without satellites— which provides superior print quality. Conversely, if the modulation voltage falls below the minimum threshold or increases above the upper limit, satellite drops will INCREASE to the point the code will be unrecognizable.

Meanwhile, some CIJ printers feature auto-modulation which allows the printer to maintain print quality without any intervention. However, others that do not have this functionality and must be manually adjusted to maintain print quality.

Advantages of CIJ Print Method

Technology behind CIJ printers may be over 150 years old, but their use in food, beverage, wire & cable, pharmaceutical, and industrial applications continues to grow. CIJ printers offer several advantages over other printing technologies. For example, even at high speeds, CIJ printers provide excellent print quality on a wide array of substrates.

The non-contact printhead is more tolerant of variances in packaging; flat to round or rigid to flexible (You can even print on oblong eggshells), CIJ can print on them all. Additionally, unlike other printing technologies, CIJ has the flexibility to use many different colored inks which provides unparalleled contrast on a myriad of substrate colors. And to think all of this versatility and reliability starts with THE PERFECT DROP.

The wrap up...one perfect code at a time

According to the Digital Journal, the industrial inkjet printers market was valued at $9,176.42 million USD in 2021 and is projected to reach $15,376.76 million USD by 2028. Clearly this long standing technology is showing no signs of slowing down, and it is all the more reason to have the confidence in the industrial inkjet technology you are using on your production line.

Domino has the expertise and key partners for the best solutions in primary coding technology. Let our experience guide you to achieving the "perfect code".

If you are looking for advice on your particular packaging application, or want to compare our perfect drop against what you currently use, get in touch with your local Domino Account Manger, or connect with me on LinkedIn or email directly (eric.corzine@domino-na.com).