Why older Serialization Systems are increasing your risk of failure, non-compliance, and downtime — and what the research says about it

In the world of pharma and life sciences manufacturing, coding and marking serialization systems are critical. They ensure regulatory compliance, traceability, and patient safety. But many of these systems, installed during the early days of global serialization, are now nearing or exceeding a decade in service.

At first glance, they still work. But that doesn’t mean they’re working well — or safely. An increasing body of data shows a clear connection between ageing equipment and operational risk.

To begin with, serialization systems are an interconnected network of components — including conveyors and guides, product handling systems, vision and verification cameras, rejection mechanisms, software controllers, triggers, sensors, data cables, and integration layers with MES or ERP platforms. Each of these subsystems plays a vital role in ensuring accurate, legible, and traceable codes — and each introduces its own type of vulnerability. Mechanical parts like conveyors or handling rails may wear out physically over time, while electronic elements like triggers, sensors, and cameras are prone to drift, calibration issues, or outright failure. To complicate matters further, many of these elements were installed at different times, from different vendors, and may be ageing at different rates. This fragmented ageing adds a new layer of complexity, where a single failure point — whether mechanical, electronic, or digital — can disrupt the entire serialization process and increase both compliance and operational risk.

Equipment Age = Higher Downtime and Failure Risk

Research across manufacturing sectors points to a common truth: old equipment breaks more often. A 2018 Plant Engineering study found that 44% of all unplanned downtime is caused by aging machinery — more than any other factor. In a 2023 survey of pharma producers, 50% of downtime events were tied to aging or physically deteriorating equipment.

For coding systems, the risk is especially acute. CIJ printers rely on ageing pumps and ink filters. Laser coders lose beam intensity and degrade. TTO mechanisms wear from constant motion.

These issues manifest as:

- More frequent stoppages

- Inconsistent print performance

- Difficulty sourcing replacement parts

- Longer repair cycles

This is what we describe as a “false economy.” Printers that seem cheap to keep can cost far more in unexpected downtime, maintenance, and production loss.

And those costs go beyond lost time. While average downtime across manufacturing can be between $10.000 to $260,000 per hour, in pharmaceutical settings, the consequences are often more severe. A 2025 industry report shows that UK pharma manufacturers can lose £1M–£5M per hour during unplanned stoppages — roughly $1.25M–$6.25M USD — due to production, product loss, and regulatory implications.

One of the key reasons? Hygiene protocols. Many pharmaceutical products, especially oral solid dose forms like tablets and capsules, have strict time limits between production and primary packaging. Once exposed to air, active ingredients and coatings can degrade or become non-compliant. If the line stops — even for a few hours — and those products can’t be sealed in time, entire batches may need to be discarded due to contamination or sterility concerns.

In short: a single ageing serialization system failure can not only stop the line, it can wipe out an entire day’s production. The cost is measured not just in dollars, but in trust, inventory loss, and regulatory exposure.

Declining Print Quality: A Silent Compliance Risk

Not all failures are dramatic. In many cases, aging coders continue operating — just poorly.

A 2022 study on industrial inkjet systems showed clear, measurable print degradation over time, with print consistency and drop placement declining the longer the equipment was in use. In pharma, even a slightly faded expiry date or blurred barcode can become a serious compliance issue.

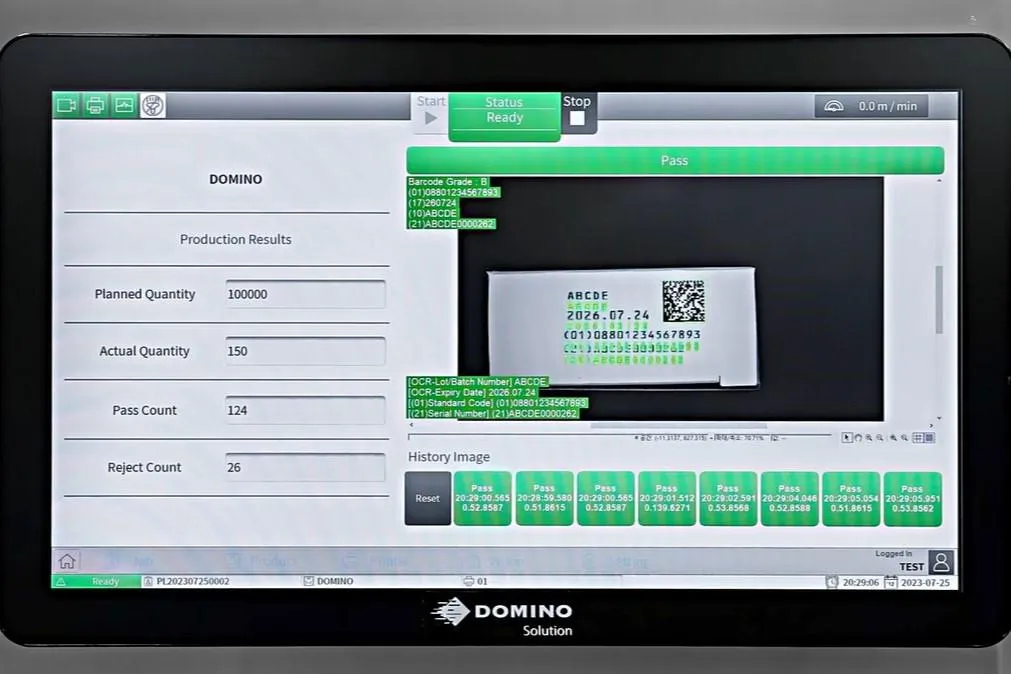

But as mentioned earlier, print quality doesn’t depend on the printer alone. Product handling plays a crucial role in producing a clear, scannable code. If products shift, tilt, or vibrate during printing, the code may become misaligned or distorted. Similarly, vibrations or fluctuating speeds in the conveyor system can affect print accuracy. A trigger failure can result in mispositioned codes, while a malfunction in the vision or rejection system may allow these errors to pass unnoticed — potentially reaching the final consumer. In pharma, that could mean a recall, a compliance violation, or worse: a patient safety risk.

Packaging experts highlight that:

- Print quality issues can lead to product recalls

- Errors may not be caught until QA — or post-distribution

- Faint, misaligned, or incomplete codes may fail audit standards

In 2018 alone, over a million medical devices were recalled due to printing and labeling errors. It’s not difficult to imagine a faded data matrix code or misprinted lot number triggering similar action in pharma or biotech.

Maintenance Costs and Complexity Rise with Age

As systems age, they demand more attention. Increased cleaning, calibration, and parts replacement become routine — which adds complexity, labor costs, and risk.

According to reliability studies (like those summarized by Balluff), only 15–30% of equipment failures are directly age-related. These are wear-out failures that spike late in life — like a printhead finally wearing down or a motor giving out. But the remaining 70–85% of failures are random — meaning they can occur at any time and aren’t easy to predict.

What’s more concerning is that aged equipment becomes more vulnerable to these “random” failures, especially as components wear and monitoring systems fall out of date. An older printer that lacks self-diagnostics or predictive alerts might continue running until it fails catastrophically — and unexpectedly.

The Cost of Non-Compliance

In life sciences, serialization is not just a utility — it’s a validated, auditable step in a regulated process. And yet, older systems often lack the tools needed to comply with today’s regulatory expectations. They may not log print events, store user access records, or integrate with traceability systems. This lack of visibility becomes a major issue during inspections or when trying to investigate deviations.

In contrast, modern systems are often equipped with:

- Real-time code verification and rejection

- Cloud-based diagnostics

- Electronic audit trails

- Integration with serialisation and MES platforms

Aging Serialization Systems: How to Spot the Risk

Many manufacturers continue using legacy systems long past their prime, often because "they still run." But performance often declines gradually — until a failure or audit makes the problem visible. Here are a few early warning signs your equipment may be ageing out:

- Increasing print errors or quality drift

- Difficulty sourcing spare parts or firmware updates

- Lack of compatibility with current compliance systems

- Rising frequency of manual interventions

- Unpredictable downtime

In regulated environments, where every code must be perfect, even one failure is one too many.

What can you do?

The best-performing pharma operations are taking a proactive approach. Instead of waiting for equipment to fail, they’re:

- Checking and updating legacy systems before they cross critical failure thresholds

- Upgrading to connected systems that support compliance, traceability, and audit readiness

- Using predictive maintenance tools to identify wear patterns and prevent line stops

- Investing in digital diagnostics and remote support, ensuring issues are caught early and resolved fast

According to maintenance and operations surveys, upgrading aging machinery is ranked the #1 strategy for reducing unplanned downtime — well ahead of increasing service contracts or staff training.

Final Takeaway

Aging serialization systems might still be working. But that doesn’t mean they’re safe, compliant, or cost-effective.

The science is clear: older serialization systems are more prone to failure, quality degradation, and maintenance fatigue. In regulated industries, those issues translate directly to financial loss and compliance exposure.

If your serialization system was installed during the first wave — 8 to 10 years ago — it may be time for a thorough health check. Not because it's failing, but because small issues can build up quietly over time. An expert review can help you spot risks early, identify what still works well, and plan smart updates that protect your performance and compliance.

Now is the time to assess the health of your equipment and future-proof your line before it costs you a lot more than a new printer ever would.

Sources:

Do you want to learn more about serialization?

Serialization is the single greatest challenge the printing industry has faced in decades — and it’s not going away.

We’ve created an expert guide to help you stay ahead: from global requirements and code validation to integration best practices and sustainability.

Download the guide here.