A High-Speed Monochrome Variable Data Printing System Built for Pharma Serialization, Blister Foil, and High-Volume Packaging Applications.

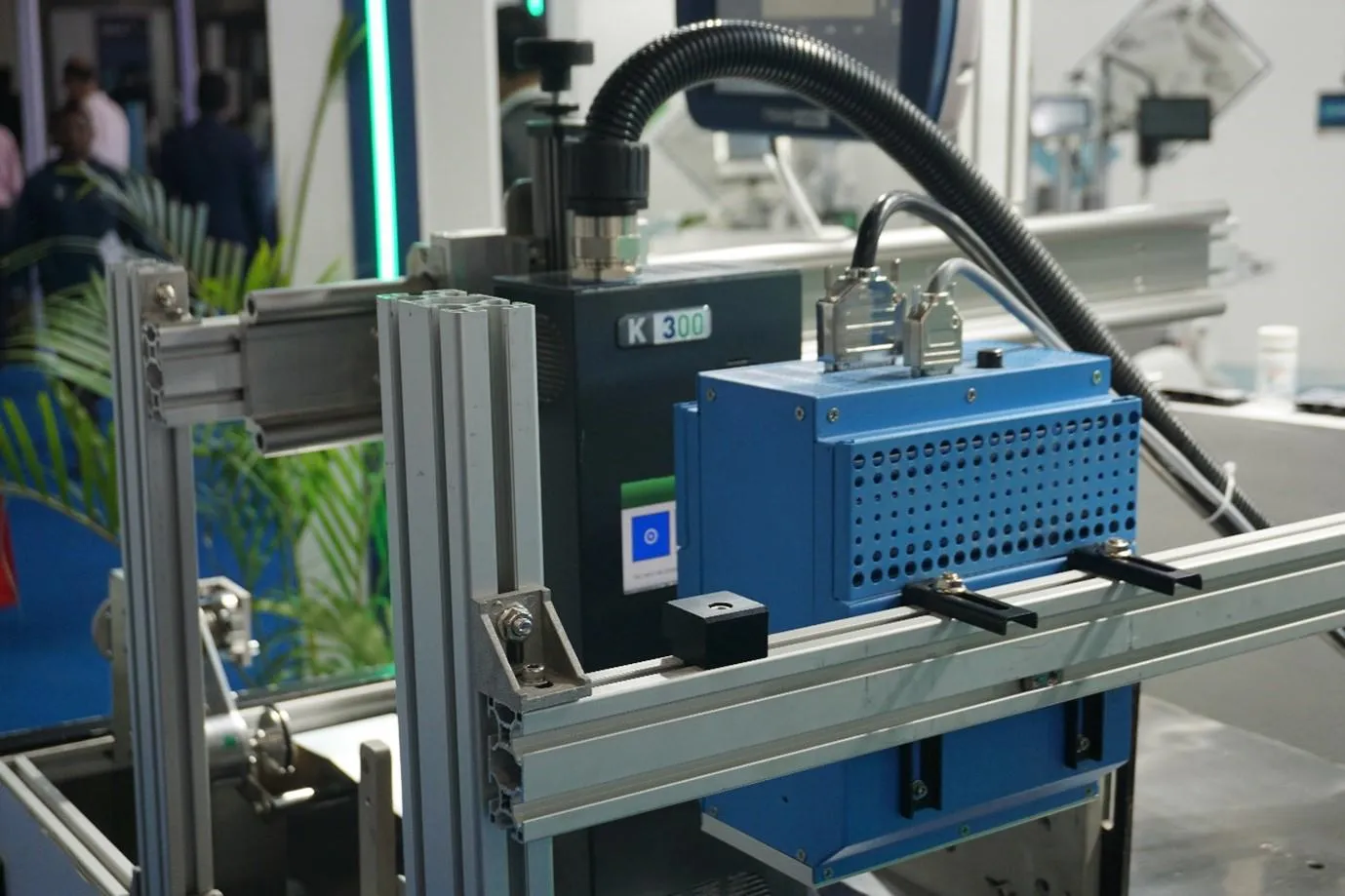

Gurugram, India – November 28, 2025: Domino Printech India has announced the launch of the Domino K300, an advanced monochrome high-speed variable data printing (VDP) system designed to meet the growing demands of pharmaceutical serialization, blister foil printing, and high-volume packaging lines. Purpose-built for accuracy, efficiency, and compliance, the K300 reinforces Domino’s leadership in industrial inkjet technologies for regulated industries while offering unmatched flexibility across multiple sectors. The system was launched during recently concluded CPHI India | PMEC 2025, in Greater Noida.

The K300 is optimized for a wide variety of pharmaceutical substrates including cartons, labels, inserts, mono cartons, and particularly aluminium blister foils, where print durability and contrast are crucial. Its advanced monochrome ink set provides excellent adhesion on foil surfaces, delivering deep optical density and long-lasting readability even in demanding supply-chain conditions.

With up to 600 x 600 dpi native print resolution, the K300 ensures superior clarity for GS1 DataMatrix codes, serialized alphanumeric content, and machine-readable barcodes. Engineered for high-throughput operations, the system supports printing speeds of up to 250 meters per minute, depending on resolution requirements-helping manufacturers maintain compliance without compromising production output. Beyond pharma, , it fits perfectly inline at a label converter or production line to meet the needs of diverse applications.

Seamless integration with serialization software and pharma MES systems ensures that pharmaceutical exporters can achieve global compliance standards with confidence, while the system’s low-downtime design and automated monitoring reduce operational risk.

The adoption of GS1-powered 2D codes and QR codes for retail packaging allows for variable data such as best-before dates, batch codes, and serialization to be included within each code. This increases the demand for short-run production, reduced stockholding of generic packaging, and frequent variant switching. The K300 enables manufacturers to meet these challenges without compromising line speed or efficiency.

“The introduction of the K300 reflects Domino’s continued commitment to empowering India’s pharmaceutical sector with cutting-edge printing solutions,” said Tanuj Agrawal, Managing Director, Domino Printech India. “In high-speed pharma environments-especially blister foil printing-there is no room for error. The K300 combines speed, stability, and exceptional resolution, helping manufacturers achieve global compliance with absolute confidence.”

Adding perspective from the life sciences domain, Ashu Malik, Senior General Manager – Life Sciences, Domino Printech India, commented, “Serialization and traceability have become mission-critical for pharmaceutical exporters. The K300 delivers superior code quality, reliable performance on blister foils, and smooth integration with existing production systems. It is built to meet today’s regulatory demands and tomorrow’s scalability requirements.”

The launch of the K300 strengthens Domino’s commitment to driving innovation for India and global pharma and life sciences sectors, while also supporting manufacturers across retail, mailing, and security printing. By enhancing traceability, reducing downtime, and enabling late-stage customisation, the K300 future-proofs packaging lines for the evolving demands of global supply chains.