Most coding errors are born from simple wear and tear on your industrial printer. For example a misaligned print head can cause phase errors, incorrect breakups and missing drops. Other causes of print errors stem from misuse of the coder or inappropriate installation.

But whatever the cause, the net result is the same: codes that are misaligned, difficult to read or sometimes completely illegible. And the problem almost always gets worse if left alone.

>> How to optimize your printing technology for peak performance

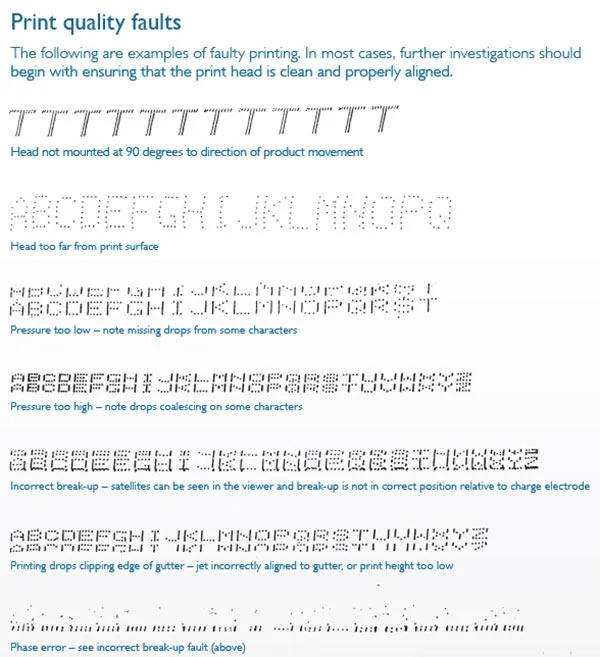

In order to troubleshoot your printer, there are some typical errors that you should look for before calling in the Domino support cavalry. With most industrial printer errors, the first thing to do is check whether the print head is clean and properly aligned.

Problems with ink pressure are another common cause of printing errors. If both the head and ink pressure seem to be normal that's when you might want to consider calling us. If problems continue to persist after your troubleshooting and recur frequently, it may be best to call an engineer or have us check remotely with our Domino Cloud remote service.

Prevention trumps cure

Generally, printing errors are pretty straightforward to fix. That doesn’t stop them being frustrating. Even the smallest errors can stifle productivity, bringing entire lines to a complete halt and ultimately, putting the brakes on efficiency.

How do you avoid these types of errors before they occur? Believe it or not, it's the simple things. Like any other complex machine, following your housekeeping and cleaning program will help prevent errors in the long run. But stopping them altogether could be as easy as an annual optimization routine. It’s a kitchen-sink approach to keeping your coding technology at peak performance - and it gets results.

What to Check in Your Printer

A Domino North America service specialist can visit your site to check things like ink stream alignment, ink temperature and ball fall time for viscosity. Then there’s the cooling fan, positive air pump and solenoid valves to scrutinize. And what about electrical supply, air supply and festo fittings?

In all, there are several areas on the housekeeping list - but an experienced technical engineer will be done with the full printer wellness check in less than 90 minutes. This ensures your printers have a clean bill of health and are capable of delivering optimum performance and the highest productivity possible. Week in, week out.

Interested in optimizing your printing technology?

In order for your coding and packaging operations as profitable as possible, they have to be as efficient as possible. To remain profitable and efficient, they have to stay running. That's where regular checks can come in. Simple prevention techniques like the ones discussed above will keep your industrial printer running without issue for years to come.

Or, if you are already running a bank of Domino printers, you may also want to look into our revolutionary Relax program that allows you to roll in Service and Replacement Parts costs into the initial purchase price of our industrial printers.

Whatever you choose, Domino can help you get your printer optimized, repair it from afar with Domino Cloud or send out one of our trained technicians to repair your industrial printer.