In label printing, there’s no such thing as an “average” job. Every label differs in design, substrate, ink coverage, and press setup. Yet many label converters still rely on average-based pricing models – overlooking this complexity. The result? Misquotes that erode margins, delay decisions, and weaken customer trust.

In today’s fast-paced, price-sensitive market, precision quoting isn’t just a technical upgrade – it’s a strategic imperative. It’s the difference between protecting profitability and bleeding margin. Between winning repeat business and losing customers to faster, more confident competitors.

This blog explores how timely, accurate cost calculation supports profitability – and offers practical tips to help label converters stay competitive.

Why Accurate Label Costing Matters

Accurate quoting isn’t just about getting the price right – it’s about positioning your business for long-term success.

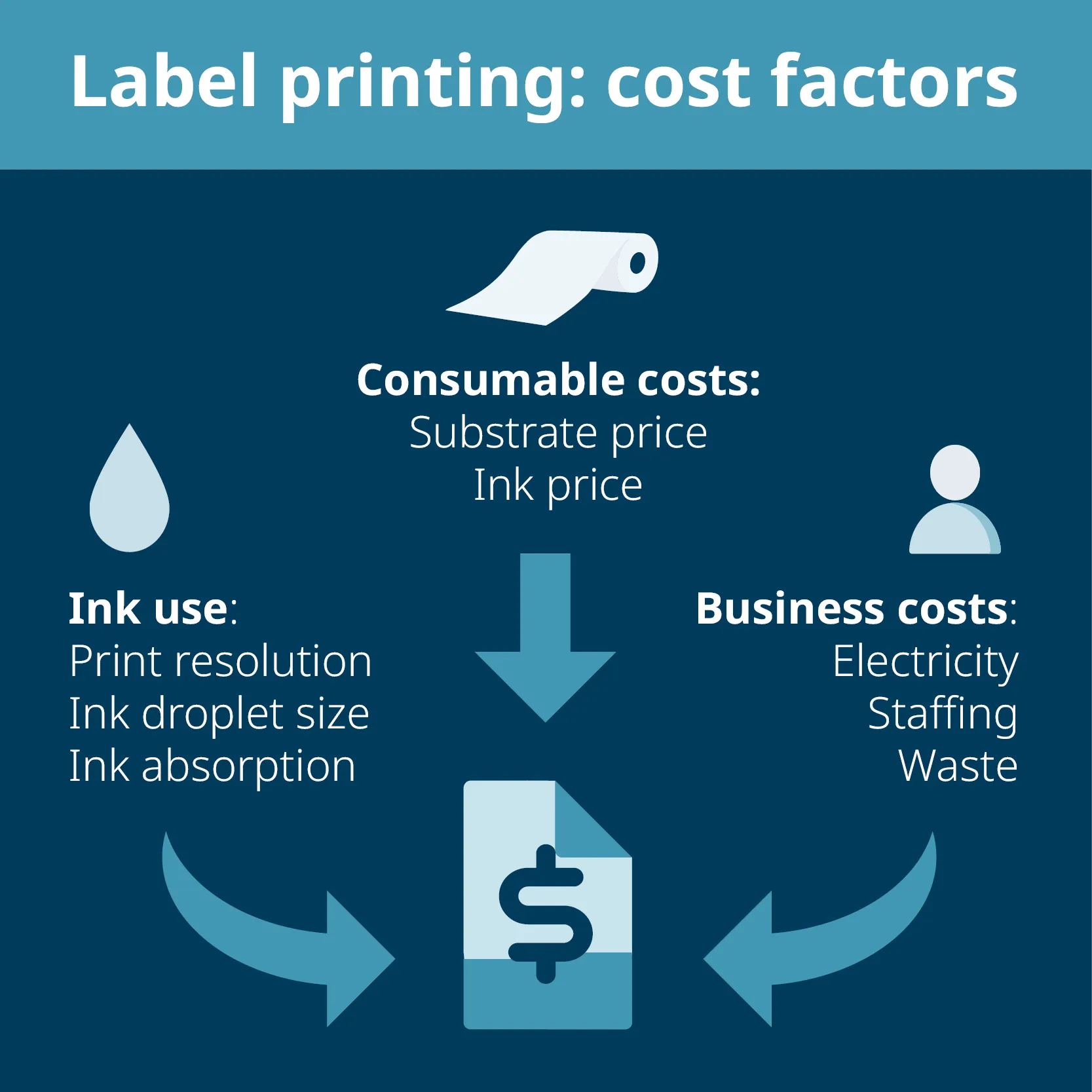

Ink and substrate costs fluctuate frequently due to tariffs and material availability, which means consumable cost per label can vary widely, making manual or average-based pricing models insufficient for maintaining profitability.

In digital printing, the cost of producing a label can even vary depending on the specific label press used. Ink consumption changes with the substrate, with porous substrates requiring more ink to achieve the desired label coverage. Factors like print resolution and ink droplet size affect ink consumption further, and colour ink prices can vary between suppliers, even within the same ink set.

Label converters operating multiple digital inkjet presses, even from the same supplier, need to generate quotes based on the specific digital equipment used. Last-minute changes, such as switching presses when the order comes in, can impact margins if costs deviate from the original estimate.

Knowing the exact cost for producing a label gives label converters the confidence to make strategic decisions, such as determining how much of a discount they can offer without incurring a loss. This is especially key when competing for, and winning, new business.

5 Tips to Protect Margins in Digital Label Printing

Harnessing digital tools to enable a data-driven approach to costing can help label converters quote more effectively. Here are five practical tips how label converters can protect their digital printing margins – gaining a competitive edge through more precise cost accuracy:

- Use real data, not averages:

Click-charge models tend to oversimplify and average out production costs, often resulting in label converters overcharging some jobs while undercharging others. A more accurate approach uses job-specific cost calculations based on actual ink consumption and substrate profiles.

- Update material costs regularly:

Accurate cost calculations depend on reliable data. It’s essential to keep the cost calculator up to date with current substrate and ink pricing to ensure accuracy.

- Utilise substrate and job profiles:

Saving and reusing job profiles on press eliminates the need to recalculate from scratch, ensures pricing consistency, and speeds up the processing of repeat orders.

- Compare substrates:

Label converters could consider differences in substrate costs and ink absorption rates, using the job cost calculator to assess ink usage across various materials. While a less porous substrate may have a higher upfront cost, it could yield ink savings that reduce overall job cost. These insights can support cost management and inform negotiations with customers seeking more budget-friendly options.

- Standardise die shapes:

Reducing the variety of label shapes and sizes offered can help lower tooling costs and simplify job costing. It also enhances operational efficiency by minimising the number of die changeovers required.

Empowering Sales Teams with Smarter Quoting Tools

Traditionally, job costing has been handled by dedicated teams of experienced print estimators. Now, digital technology makes costing accessible to the wider team. Most digital label press providers include easy-to-use cost calculators in their workflow, enabling label converters to generate cost estimates for artwork uploaded to their press.

But how can label converters balance production demands with generating quotes to secure a steady stream of orders, if the press has to stop for each quote?

Providing your sales team with offline tools, such as Domino’s Sunrise DFE Job Cost Calculator, solves this problem. As a standalone application, it empowers sales and estimating teams to generate quotes remotely, without interrupting production.

Staff no longer need to wait for press and operator availability to fulfil quote requests. They can easily create quotes by adding the artwork to the calculator. The calculator estimates the number of ink droplets per colour and length of substrate used, calculating the job estimate based on the costs held on file, including a fixed charge to cover overheads.

Using smarter tools enables faster response times and a smoother customer experience – especially for urgent jobs. When brands are under pressure, being the first to quote can be the difference between winning and losing the order.

Precision Quoting as a Competitive Advantage

In a world where every label is different, quoting with precision is no longer optional – it’s a competitive advantage. By embracing data-driven tools and empowering your team, you’re not just protecting margins. You’re building a smarter, faster, more resilient business.

Discover the Job Cost Calculator and other smart features of Domino’s Sunrise DFE.