Overview

Losan Pharma specialize in the development and production of solid dosage forms. As well as manufacturing traditional capsules, effervescent and film-coated tablets, this innovative pharmaceutical company has established itself as one of the largest manufacturers of stick packs over the last few years. Two new stick pack forming, filling and sealing lines have been purchased from MERZ for the production sites in Eschbach and Neuenburg. To complete this solution Losan Pharma also required a suitable labelling system, which included effective camera control, for printing the essential product information.

“As part of the new procurement of stick pack lines, we needed to establish a labelling system with camera control for several packaging lines operating independently of each other. We decided on the Domino G320i thermal inkjet OEM boards, inclusive of KUPvision camera control, as this solution seemed best suited to meet our

requirements.”Dr. Johannes Trapp, Head of Production at Losan Pharma GmbH

Fast Facts

- Stick pack labelling with two MERZ two and six-lane stick pack forming, filling and sealing lines, with four G320i thermal Inkjet OEM boards

- Print text is input centrally through the control computer HMI

- Print control from high performance Cognex vision systems

- Use of BK118 pharmaceutical ink (ethanol) for film applications with extremely fast drying times and high contrast

Case Study

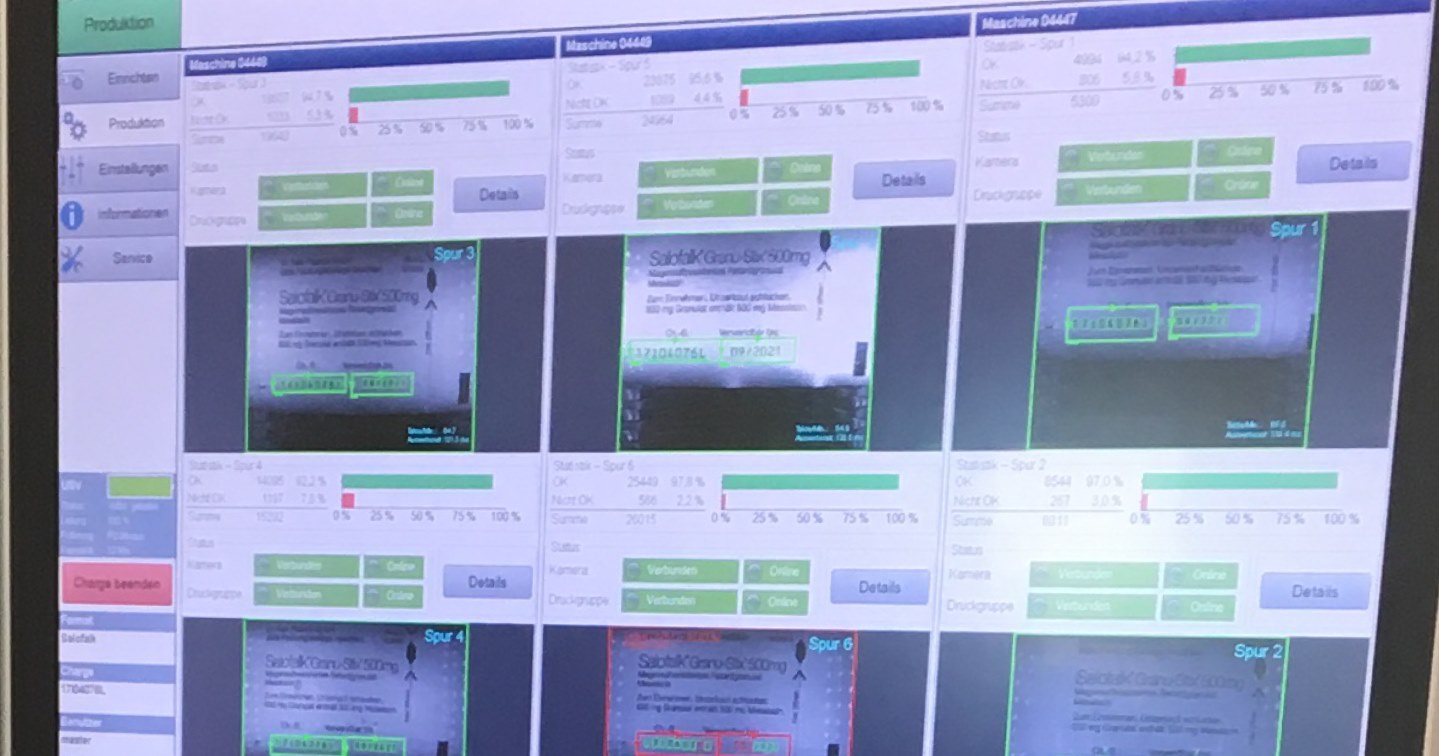

The line at the new production site in Eschbach consists of three machines with two lanes each. A Domino G320i thermal Inkjet OEM board with two heads and two cameras has been integrated into each of the two-lane machines. The system is controlled via the central control PC. Within the Neuenburg site, one stick pack forming, filling and sealing machine with two lanes, a G320i thermal inkjet OEM board with two print heads, two cameras and a control PC has been installed. Stick pack production requires central control of the labelling systems, including camera control Dr. Johannes Trapp, Head of Production at Losan Pharma GmbH, comments on the requirements: “We needed to establish an innovative labelling system with camera control for several packaging lanes operating independently of each other. For this purpose, all the printers and control cameras need to be controlled from a central control panel.”

“To meet our requirements we decided on the Domino G320i thermal inkjet OEM boards, together with KUPvision camera control, since this solution seemed best suited to meet our requirements. We also found that we could integrate both the printers and the control cameras into the MERZ stick pack machines without any issues,” continued Dr. Johannes Trapp.

The decisive factor was Domino & Krempien+Petersen’s (K+P) strong partnership. The G320i OEM board was specifically designed for original equipment manufacturers (OEMs) and system integrators and cannot only be used seamlessly in the target system, it can also be controlled through the system’s HMI environment. The four printheads in four different print groups offer OEM’s a wealth of configuration options for printing pinpoint-sharp codes at high production speeds. In addition to the print systems and in cooperation with Krempien+Petersen Qualitäts-Kontrollsysteme GmbH, Domino can provide the necessary software solution in the form of KUPvision. KUPvision is a mark & vision software, with a coherent operating concept which allows it to be intuitively and conveniently linked and used with the print and inspection systems. The software has been produced in accordance with the most recent regulations and recommendations. It also includes the latest development tools, so that it can be used in a variety of industries such as pharmaceutical, automobile and food. This software exploits all the possibilities in today’s systems and due to its modular structure, it can be adapted and enhanced to suit individual customer requirements. Thanks to the mechanical excellence of the MERZ machine manufacturers, all components could be smoothly integrated into the stick pack forming, filling and sealing machines. The solution has achieved universal approval. As Dr. Johannes Trapp confirms, Losan Pharma was won over by this complete solution and this led them to make the decision to purchase:

“Our choice fell on the Domino G320i thermal inkjet OEM boards in combination with KUPvision. We already

had a good experience with Domino’s printing solutions and the simple, intuitive operability of KUPvision simply

won us over.”Dr. Johannes Trapp

The stick pack film is produced by the two MERZ systems at a rate of up to 8.5 m/min. Downtime amounts to about 0.5 seconds and the maximum test rate is approx. 80 cycles per minute. Before the stick packs are filled, the G320i OEM boards print the batch number and expiry date. As well as the good print quality and reliability at high production speeds, the abrasion resistance is an important factor when printing the plastic film. For this reason, Losan favours the use of the special BK118 thermal inkjet pharmaceutical ink (ethanol) for film applications. This ink has fulfilled their requirement for extremely fast drying times and high contrast. Intelligent cameras from the manufacturer Cognex are used to control the print. The data is tested by means of reading the text (OCR) and then verifying it (OCV). An industrial PC with a touch screen is used to visualise the test results, the test status and the system states, as well as to parameterise the test systems after initial setup, and to store any error patterns. The KUPvision software provides the backup of all data in a standardised SQL database and thus offers the basis for optimum communication via a PSE (Plant Serialisation Execution) with the SAPERP/OER system. The test system has an interface to the G320i OEM boards, which records all the printer settings and functions in a standardised software and within an audit trail. The system is operated via menu items, which can be password enabled. In addition, all the formats are easy to set up. The variable data is entered via the control PC’s HMI. “Our expectations have been met in full. At the moment we are more than nine months into our routine 24/7 production. During this time we have experienced no machine breakdowns of any kind caused by the printing system ceasing to function. The production employees also cope very well with the new system. I would highly recommend Domino as a systems supplier,” concludes Dr. Johannes Trapp.