Coding and marking is a small but integral part of production in food, beverage and pharma plants across the globe. Legislation dictates that nothing can leave the factory unless the right code has been applied to the packaging – be it a date code or a code for identification purposes. If a product does leave without a code or an incorrect one, recalls and possible fines are costly, both in cash terms and potential impact on the manufacturer’s brand.

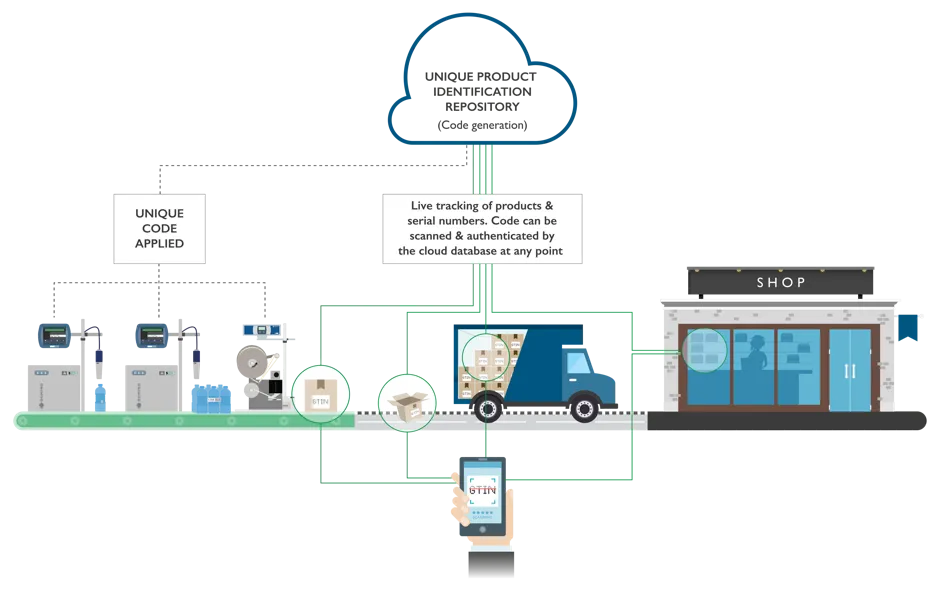

This can become more complicated in industries such as pharma or in baby food in China where regulations are being put in place to enable individual products to be tracked through the entire supply chain, verified by retailers and customers and traced back to the origin of their production.

While coding and marking safeguards consumers it adds complexity to production. The ideal is that coding and marking machines are virtually invisible on the production line – applying letters and digits to packaging as if by magic – and are never the root of unplanned downtime.

This may sound like fantasy, we are, after all, talking about machines. Machines that run out of ink, machines that get clogged up, and machines that in the hands of people can print whatever they’re instructed to do. And whether it’s a genuine mistake or a malicious act the consequences are the same – recalls, reworking and potentially fines.

From a coding and marking perspective, combatting the factors that cause unplanned downtime in production can largely be put into two groups: keeping printers running and making sure the right code gets put on the right product. At Domino, we call this maximum efficiency, our mantra for Industry 4.0.

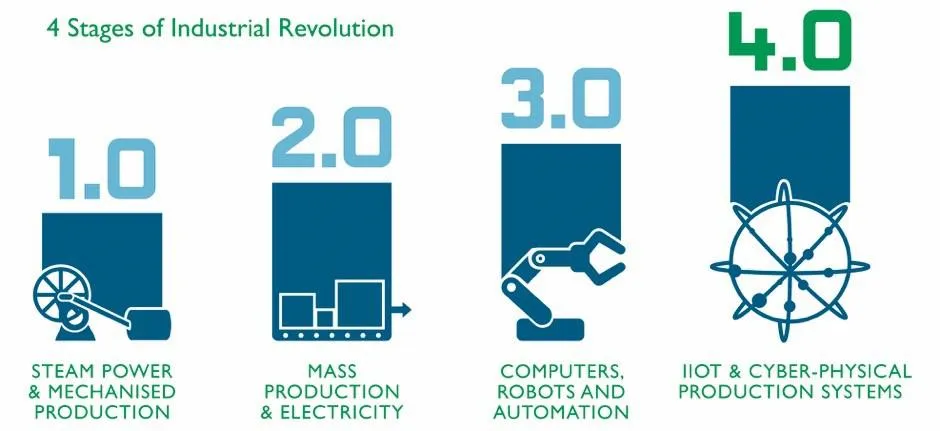

Industry 4.0 is an umbrella term for a whole bunch of technological advances that are transforming the way we manufacture. It’s as much evolution of existing automated systems (like assembly line robots or packaging equipment) as it is revolution.

The picture of Industry 4.0 is one of intelligent, autonomous factory systems integrated with the internet, making complex decisions on the fly, fed by a never-ending stream of data. In the world of the smart factory, there are no mistakes. However, Industry 4.0 isn’t an all or nothing state, it should be moulded to your business and guided by the impact it has on your bottom line. Products, technologies and new ways of doing things can be introduced bit by bit, eventually building up to a whole system optimised for maximum efficiency.

‘Being Industry 4.0’ should be thought of as a journey, rather than a single event, where improvements can be made to systems across the factory in manageable chunks ensuring that processes are set up correctly and Industry 4.0 is being used to its full potential.

It’s in the areas of big data, system integration, IoT and cloud computing that Domino is shaping Industry 4.0. Our new technologies turn our printers from dumb to intelligent, and connect them into your equipment and systems as part of one intelligent factory operation.

Domino’s iTech-x platform collects a vast array of data on printer operation – from ink and makeup levels, to wear and tear on components, this information is then sent up to Domino’s cloud databases. Our support team and engineers use the collated data to remotely diagnose faults and spot potential future issues. The data is available for customers too, accessible from any device connected to the internet.

Connecting coding and marking machines to the cloud means that keeping them working no longer requires an engineer to physically be at the machine. Instead potential issues can be identified, and faults diagnosed in advance many miles away. Reactive fixing has become proactive servicing.

Our latest continuous inkjet (CIJ) printers automatically monitor ink and makeup levels, adjusting them depending on environmental conditions so that it’s optimised for the print head, whether it’s operating in a hot, humid factory or a cold, dry one. By building this intelligence into our printers we can ensure the printing of high-quality codes, thus reduce the likelihood of products being recalled and unplanned downtime to clean and adjust printers.

Another common cause of unplanned downtime is human coding error. To solve this Domino’s QuickDesign software integrates printers with business systems such as MES and ERP so that they can receive coding messages, data and instructions automatically during production runs without the need for human intervention.

Integrating printers and other components like PLCs, HMIs with larger factory equipment and systems depends on their ability to share data reliably and securely. Communication standards such as OPC-UA and PackML remove the need for developing custom control software to interface between devices. As such Domino is building them into the iTech-x platform. In fact, through our membership of organisations such as the OPC Foundation, and the Organisation for Machine Automation and Control (OMAC), we’re taking an active role in the development and promotion of communication standards.

The technologies above are at the beginning of Domino’s journey to shape Industry 4.0. A journey to make coding errors and unplanned downtime caused by coding and marking machines a thing of the past. To learn more, download our white paper today.