As lithium ion batteries have become more ubiquitous in our everyday world, the value of tracking and tracing these batteries has grown. The reason for this greater significance is that the age of batteries is vital information for both the user and the manufacturer of the finished good - whether it's a laptop or an electric car. In addition, should there be a battery recall, you can easily isolate to the specific batches with bright, easy to locate, durable codes.

Why are these codes so important?

It is important to make sure that your products are marked with the codes they require to offer users adequate information and meet legislative requirements. But how do you create accurate, durable product codes on small, tough components, such as batteries, without compromising on production costs?

What industrial printing technologies are capable of creating these codes?

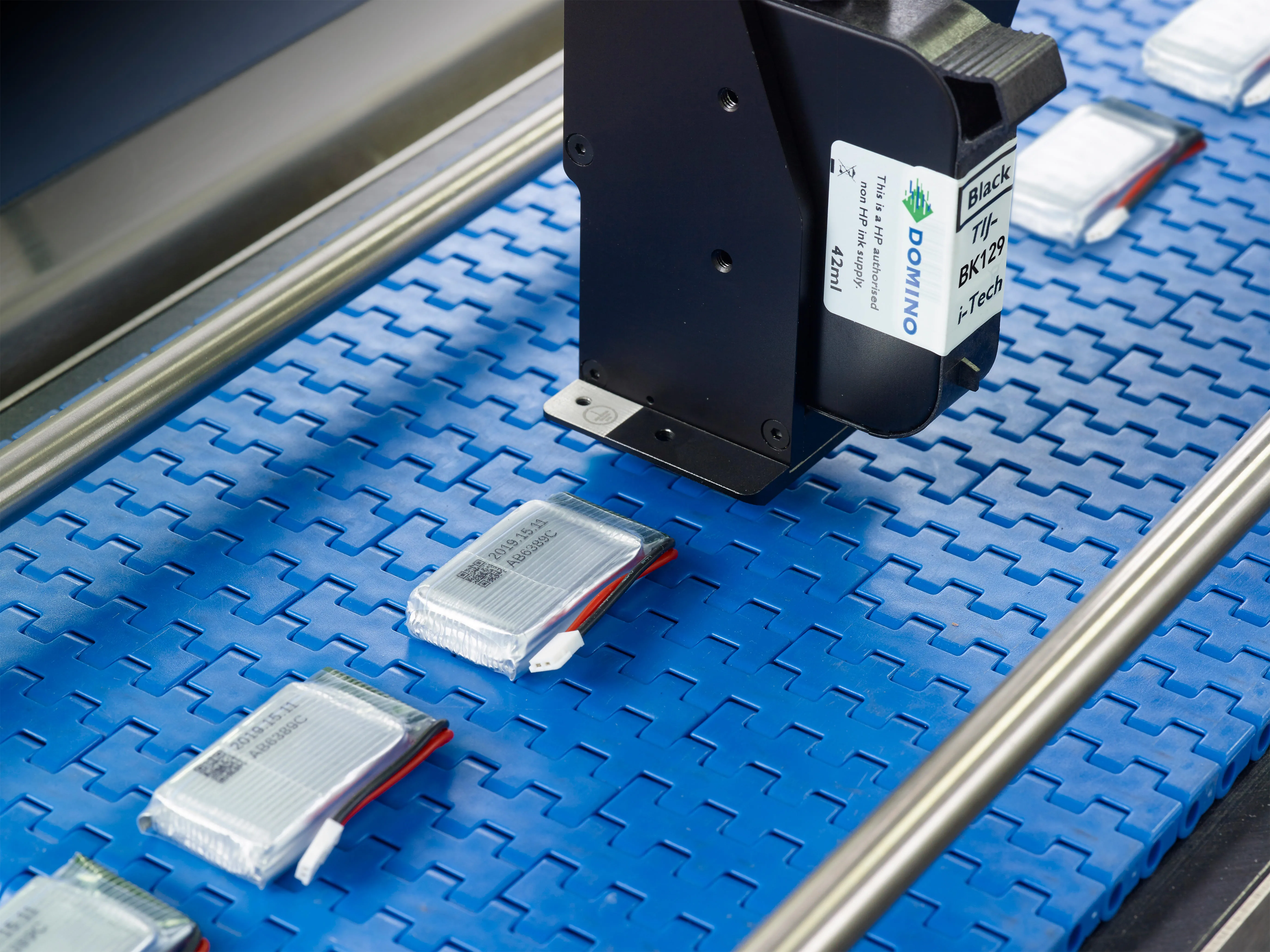

Both Domino North America's continuous and thermal Inkjet printing solutions can code your batteries with accurate, durable text, graphics and 2D Data Matrix codes – even when working with precision production methods and tough-to-mark materials. Our CIJ printers combine high-performance print heads with substrate-specific inks, designed to withstand the harshest of post-print processes, and come in a variety of colors for maximum contrast on all surfaces.

Meanwhile, our Tij printers also offer high-quality performance and are similarly designed to be compact and flexible – allowing them to integrate into your existing production process and saving on installation costs and time.

For a complete coding solution, you might also like to think about combining different printer technologies with our advanced package labeling technologies – offering performance and quality across your entire production and packaging lines.

Our Automation and Integration Services help make the coding process safer and prevent errors from happening.

Domino Automation and Designer, our software tools for centralized label management and automated deployment, are designed to boost your production efficiency: streamline operations and minimize waste.

Using Domino Automation you can create messages centrally and automatically pass them down to all Domino printers on your production.

- Design and manage labels at a single location: our intuitive label design system enables using a universal interface, keeping training needs at a minimum.

- Easily manage users and their permissions: security features like Active Directory Integration enable using your existing IT network, and simplify user management.

- Full audit trail for the management of production changes: version control provides the ability for approval and roll-back procedures.