Hold on to your honey-glazed carrots: is there a revolution afoot in the fruit and veg aisle? As supermarkets wise up to the benefits of replacing sticky labels with laser printing, we look at five issues that manufacturers, packagers and retailers must be aware of for the new coding development to truly take off in the future.

Laser printing onto fruit and veg: what’s all the fuss about? Environmental efficiency and cost savings. Environmentally, replacing those little sticky labels with laser coding could create huge savings relating to adhesive labels, energy and CO2 emissions.

Many brands have started rolling out the technology. Dutch fruit and veg supplier Nature & More and Swedish supermarket ICA have joined forces to run the largest laser printing trial to date. Currently, they are replacing sticky labels on organic avocados and sweet potatoes with a laser mark.

Meanwhile, a major UK retailer says that moving from sticker labels to lasering will save ten tonnes of labels and backing paper and five tonnes of adhesive every year - and that’s just on avocados. In more good news for Mother Nature, laser coding produces less than 1% of the carbon emissions needed to create a sticker of similar size.

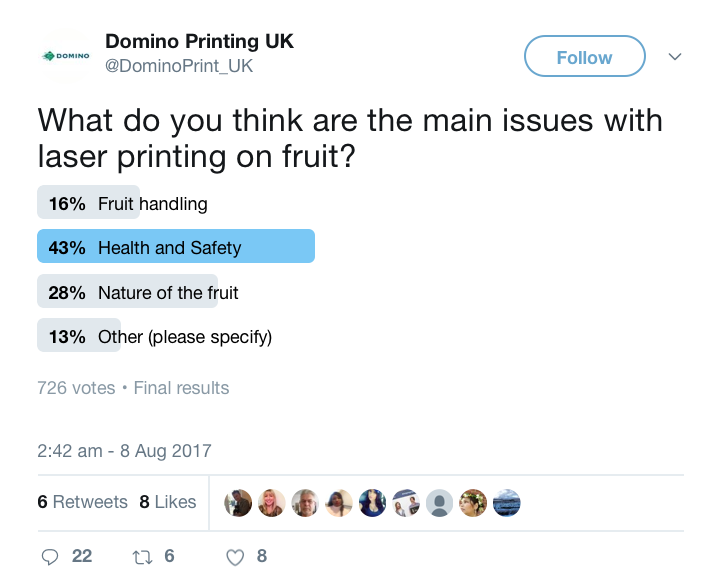

Despite these eco benefits, lasering onto fruit and veg is a potential banana skin for both retailers and processing and packaging specialists - as we discovered in our recent Twitter poll. Consumers have concerns about the lasering process harming their food. Meanwhile, the fact that fruit and veg come in all different shapes and sizes provides a stumbling block on the production line.

However, here are five things that manufacturers, coding specialists and retailers should be aware of.

1. Health and safety

Most people tend to associate lasers with danger. 43% of our poll respondents listed health and safety as a concern associated with laser printing onto fruit and veg. There’s a genuine fear among consumers that food products featuring laser coding will be unsafe to eat.

As you probably know, laser coding fruit and veg works by shining intense light onto the outer layer of the produce. This removes pigment from the skin to leave a mark that can communicate best before, country of origin and traceability information or simply a logo.

Furthermore, research at Florida University has shown that the technique does not result in any increase in decay or microbiotic contamination. However, this study has been carried out on waxed citrus fruits, this technique of waxing the fruit is not routinely done in all countries. As a result, companies must consider all options and factors as considered in this blog.

Education and further research and testing are what’s required to allay fears and understand the real long term implications. The industry must also be careful about the language that’s used to describe laser coding technology. The marks that lasering leaves on produce have been called “tattoos”. This suggests that ink is involved in the process and could easily add to consumer doubt.

2. Changes to the characteristics of produce

28% of our poll respondents were concerned about lasering impacting the taste, texture, ripeness or shelf-life of fruit and veg. The report mentioned earlier also points out that that lasering citrus products can indeed result in a deterioration of skin quality. Following initial success in terms of packaging reduction, a trial with lasering oranges was suspended after it was found that the citrus peel was “healing” itself. You may find that sometimes you need to put a coating on the skin to make it legible.

Yet for a wide range of produce - including avocados, sweet potatoes, cucumbers and coconuts - lasering may be a viable solution.

3. Readability and legibility

Apples don’t come on reams of A4. Bananas can be big or small, with wildly different curvatures. In short: fruit and veg comes in all different shapes and sizes. That has the potential to make life difficult on the production line when it comes to applying codes with lasers and ensuring the resulting mark is readable. The right setup, handling systems and overall infrastructure is key and potentially a “deal breaker” for the technology - and 16% of our poll respondents agree.

Another thing for coding specialists and retailers to consider is that fruit and veg tends to be delicate. Apples, for example, can be bruised easily if they are bumped and buffeted on the production line. Likewise, things could get messy fast with delicate fruits like peaches or oranges, though the solution may be better leant to more thick-skinned fruit such as Avocadoes. The end result however is the same; if the code cannot be read, the solution may be futile.

4. Throughput

If produce is damaged on the production line, consumers won’t buy it. There has to be an element of quality control on the production line to make sure produce is of the standard you would expect post-marking. This has obvious impacts on the speed at which produce can pass through the production line. And speed is linked to profit.

As the lasers need accurate fruit placement, the process is slow, say 1 - 2 seconds of printing plus any loading and unloading. Again, the right setup on the production line is crucial to maximise speed without compromising the quality of produce.

On production lines of slow throughput however, where there is a high price for each rarer or more sought-after item, Hass Avocadoes for example, this problem can be overcome as the speed is immediately expected to not be as high. In fact, the producers can go even further by lasering on their own logo as a mark of quality-assurance, bolstering brand awareness and loyalty.

If you need some advice...

The transition from sticky labels to laser coding fruit and veg has fabulous eco-benefits and potential savings to overall costs in delivering fruit and vegetables to shelves at a store near you. Yet there are hurdles and questions along the themes of the physical and biological property of fruit, health and safety implications, production line handling doubts, as well as the readability of the final printed code.

These need to be researched, tested and overcome if this technology is to be rolled out successfully across all fruit and vegetable varieties.

Would you like a further deep-dive into our expertise across laser technologies and the food sectors? Click the links to find out more.