Medicines for the US market are predominantly packed in bottles, with statutory information printed on labels affixed to these bottles. As Pharmaceutical manufacturers are gearing up to meet the DSCSA (Drug Supply Chain Security Act, section 582(b)(2)(A)), we have carried out a comprehensive study to help them in choosing the most suitable and versatile technology for coding onto labels.

With the implementation timeline extended until November 2018, we are certain this study will help the industry in making an informed decision in selecting the optimum coding technology for their labelling lines.

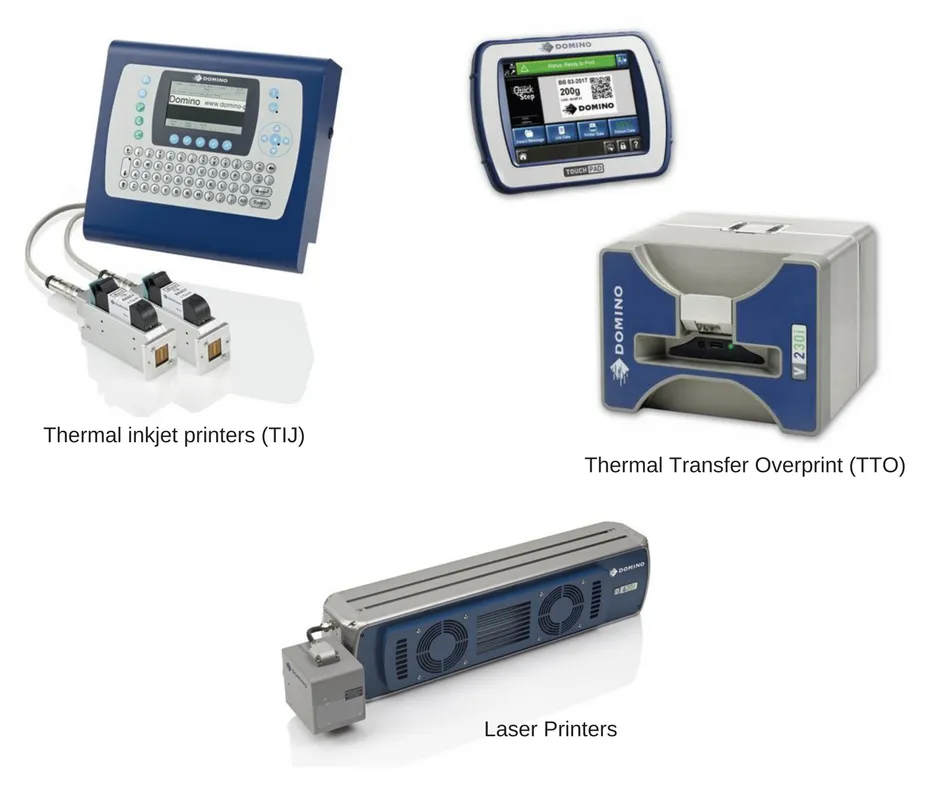

Thermal Transfer Technology (TTO), Thermal Ink Jet Technology (TIJ) and Laser printers are time tested and widely proven technologies for coding on different packaging materials. TTO is a ribbon-based technology which enables printing of high resolution codes on flexible materials like laminates, pouches and labels. Its performance is proven in a wide range of industries across the globe. It is essentially a contact coding technology. TIJ is an ink-based technology which has proven its performance in serialisation of millions of cartons globally. With Laser technology, coding is achieved by etching or vaporising the surface layer of a substrate leaving an indelible permanent mark.

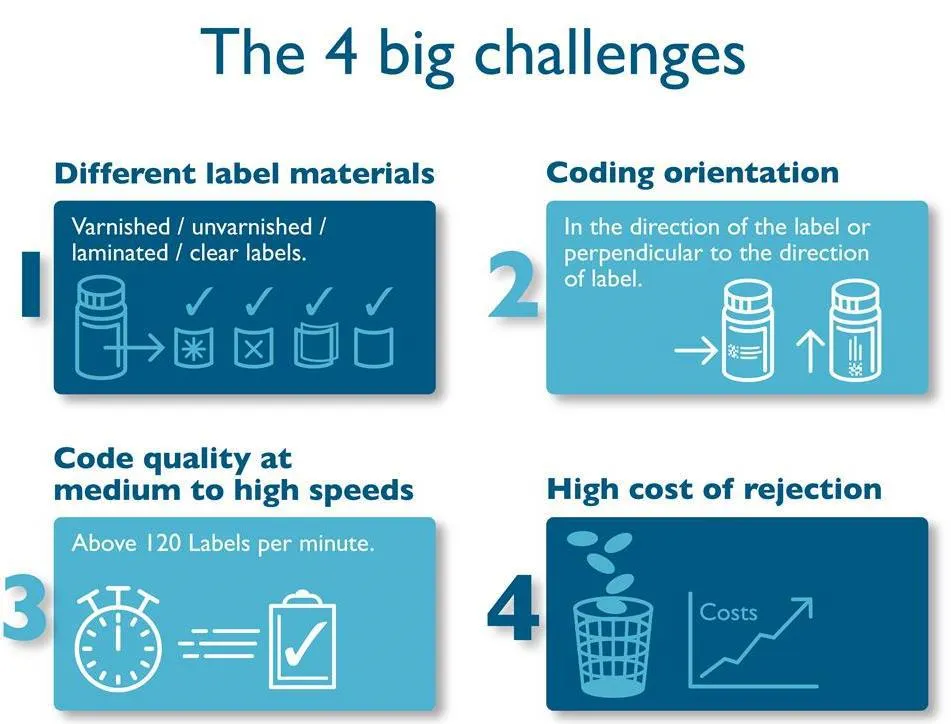

The pharmaceutical industry is grappling to choose the optimum technology for coding on labels for bottle serialisation.

The most suitable coding technologies that are available for manufacturers to apply unique identification and serialisation codes on the labels (which will be applied to bottles) are thermal Inkjet, thermal transfer overprinting and laser printers. An informed decision will help in addressing current as well as future coding requirements.

The remainder of this blog concentrates on thermal transfer overprinting (TTO) - for more general information and details on thermal Inkjet and laser technologies, please read our blog: 4 Item-level Serialisation Challenges for Pharmaceutical Businesses

The table below analyses TTO technology features with the objective of addressing the 4 big challenges in serialising labels:

This analysis clearly establishes the advantages of choosing TTO technology for label serialisation.

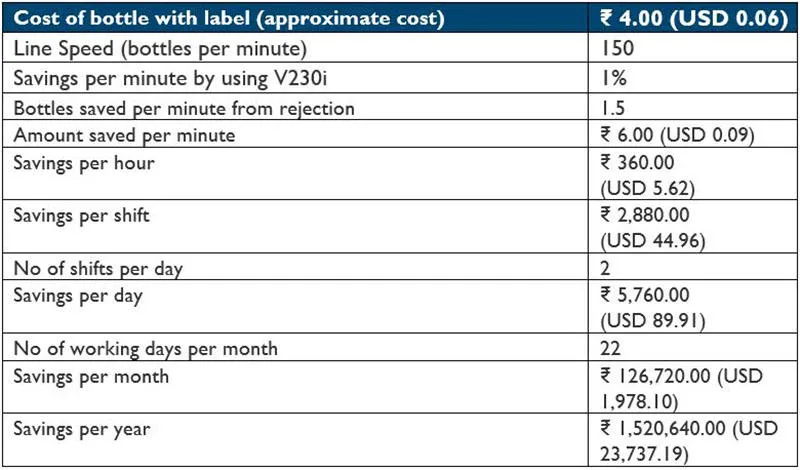

Case study for a production line in India: impact of rejection rate on operational costs

- To understand the impact of a high rejection ratio on the operational cost, we have illustrated a case study for a manufacturer in India: Labels commonly used by Contract Manufacturing Organisations (CMOs) in India are often a mix of varnished, unvarnished and plastic labels depending on the label design of the innovators, for whom these medicines are packed. The effect of vibrations in the labeling line at higher speeds is nullified by TTO, as it holds the label firmly while printing. Due to this, the CMOs benefit from Domino’s V230i TTO printer.

- Line Speed – 150 labels per minute

- Rejection rate using other technology – 2%

- Rejection rate with Domino V230i TTO – 1% (actual reject rates are less than 1%)

The codes on labels are scanned using 360-degree camera scanners and bottles with defective codes being rejected. It is not just the label but also the bottle which gets rejected.

A summary of the potential savings achieved with the Domino V230i Thermal Transfer Overprinter is listed here, although pricing is in rupees. A quick use of an online exhcange rate calculator will provide indications of the financials involved.

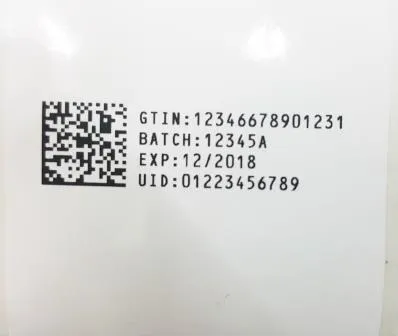

Image of a label coded with Domino V230i TTO, grade “A”:

Image of the Domino V230i TTO installation on bottle labelling line:

Customised labeller bracket

Domino’s labeller bracket provides great operator experience with the flexibility of changing the printer orientation on the X axis as well as Y axis, enabling flexibility to code on different sizes of labels. The printer orientation can also be changed to suit the coding window orientation of labels.

Contact us to find out more about the coding technologies available for the pharmaceutical industry.