Digital printing has revolutionised the world of packaging and labels, offering an alternative to traditional printing methods like lithography (litho), flexography (flexo), and gravure. With its ability for near instantaneous change over, exceptional flexibility, and cost-effectiveness, digital printing is transforming the way that packaging and label converters can serve their customers.

In this blog, we will delve into the world of digital printing, explore how digital printing is disrupting the packaging and labels industry, and the advantages it brings.

What is digital printing?

Digital printing is a printing method where digital versions of files are transferred onto a printing material without the need for traditional printing plates or cylinders. Inkjet digital printing involves the use of specialised digital printers that precisely deposit ink onto the surface of materials, creating high-quality prints with exceptional accuracy and detail.

Digital printing has gained significant traction in the packaging and labels industry in recent years due to its unique advantages over traditional printing methods, which we will explore further in the sections below.

The advantages of digital printing

Digital printing for packaging brings a multitude of advantages, particularly in terms of productivity and waste reduction.

Firstly, it offers significant cost savings for short print runs. Traditional printing methods often require costly setup processes, such as plate making, which can be inefficient and expensive for smaller production quantities. Digital printing eliminates these setup costs, making it a more cost-effective option for short runs.

Digital presses also use much less material for changeovers, meaning that there can be huge material savings – this is not only important when media is scarce, it also saves costs, and contributes to a more sustainable approach by reducing paper and ink waste.

Digital printing in packaging and labels

With digital printing, converters can offer brands affordable short-run packaging. As digital printing does not require plates to be created for each change in design, shorter run lengths are much more economical. This means that converters can offer brands opportunities to create unique packaging designs for different market segments, regional variations, or promotional campaigns. With digital printing, design changes can be both rapid and cost-effective, allowing brand owners to quickly adapt to changing consumer preferences and market trends.

Another key area for digital printing is the application of variable data. With digitally printed labels and packaging, converters can offer brands solutions for more granular product data, including barcodes, serial numbers, and unique 2D Codes for product tracking and inventory management.

It is important to note that traditional printing processes such as litho, flexo, and gravure still have their place, particularly in high-volume print runs. In certain scenarios, a hybrid approach combining traditional and digital printing may be the most suitable, leveraging the benefits of both methods to suit project-specific requirements.

Label presses and corrugated packaging printers

Digital printing has opened up a range of possibilities for packaging, and several notable presses, including those offered by Domino, cater specifically to packaging and label converters.

Colour label presses

Colour label presses, such as Domino’s N-Series range, are digital printers designed for high-quality label production. They excel at printing vibrant and detailed labels with variable data. These presses can handle a variety of label materials, including self-adhesive papers, films, and synthetic substrates. They offer quick setup times, allowing for on-demand printing and customisation.

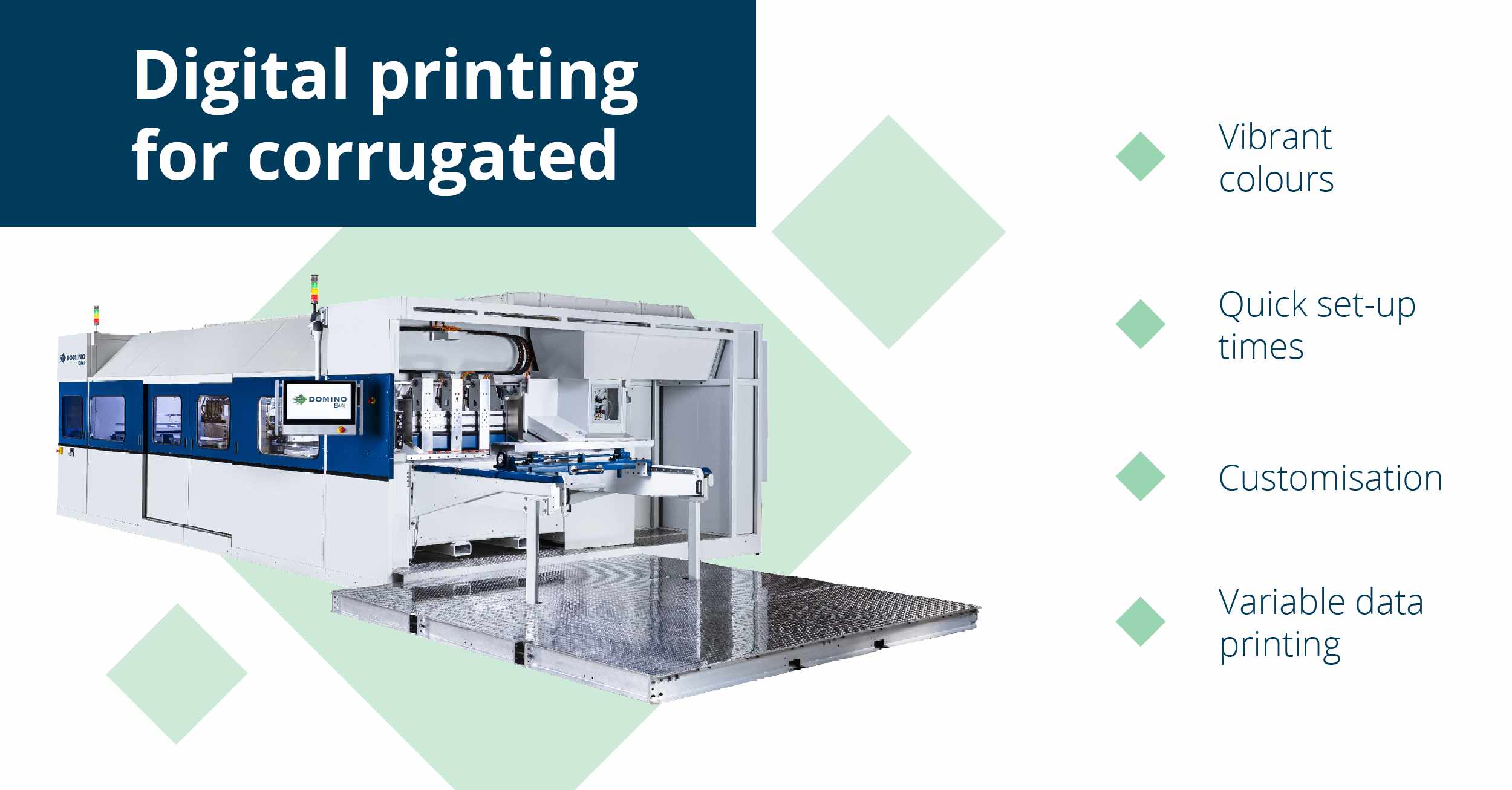

Corrugated printers

Corrugated single-pass printers, such as Domino’s X630i, are specifically designed for printing on corrugated boards used in packaging applications such as boxes, displays, and transit packaging. They are designed to replace traditional short- to medium-run printing methods such as lithographic, flexographic, and preprint. These printers offer customisation and variable data capabilities, allowing packaging and converters to incorporate personalised information, branding elements, and unique designs into each corrugated box.

By leveraging these digital printing technologies, packaging and label converters can streamline packaging production, reduce lead times, and offer brands greater flexibility in design and customisation. Whether it’s producing vibrant labels or eye-catching corrugated packaging, digital printers dedicated to packaging applications offer the versatility and efficiency required to meet the industry’s evolving demands.

Conclusion

Digital printing is a game-changer in the world of packaging and labels.

While traditional printing processes still hold value, the rise of digital printing offers exciting possibilities for customisation, speed, and cost savings. As technology continues to advance, digital printing is set to shape the future of packaging and labels, helping converters to stand out in a competitive market.

For packaging and label converters looking to future-proof their business, the time to act is now.

Discover more about Domino’s digital printing solutions for labels and packaging: https://tinyurl.com/36zweuae