Artificial Intelligence (AI) is reshaping the printing industry, offering a wide range of tools that boost productivity, unlock smarter customer insights, and enhance creativity across converter operations. For label and packaging converters, it’s no longer a question of whether they will adopt AI tools, but how quickly they can implement them – if they haven’t already.

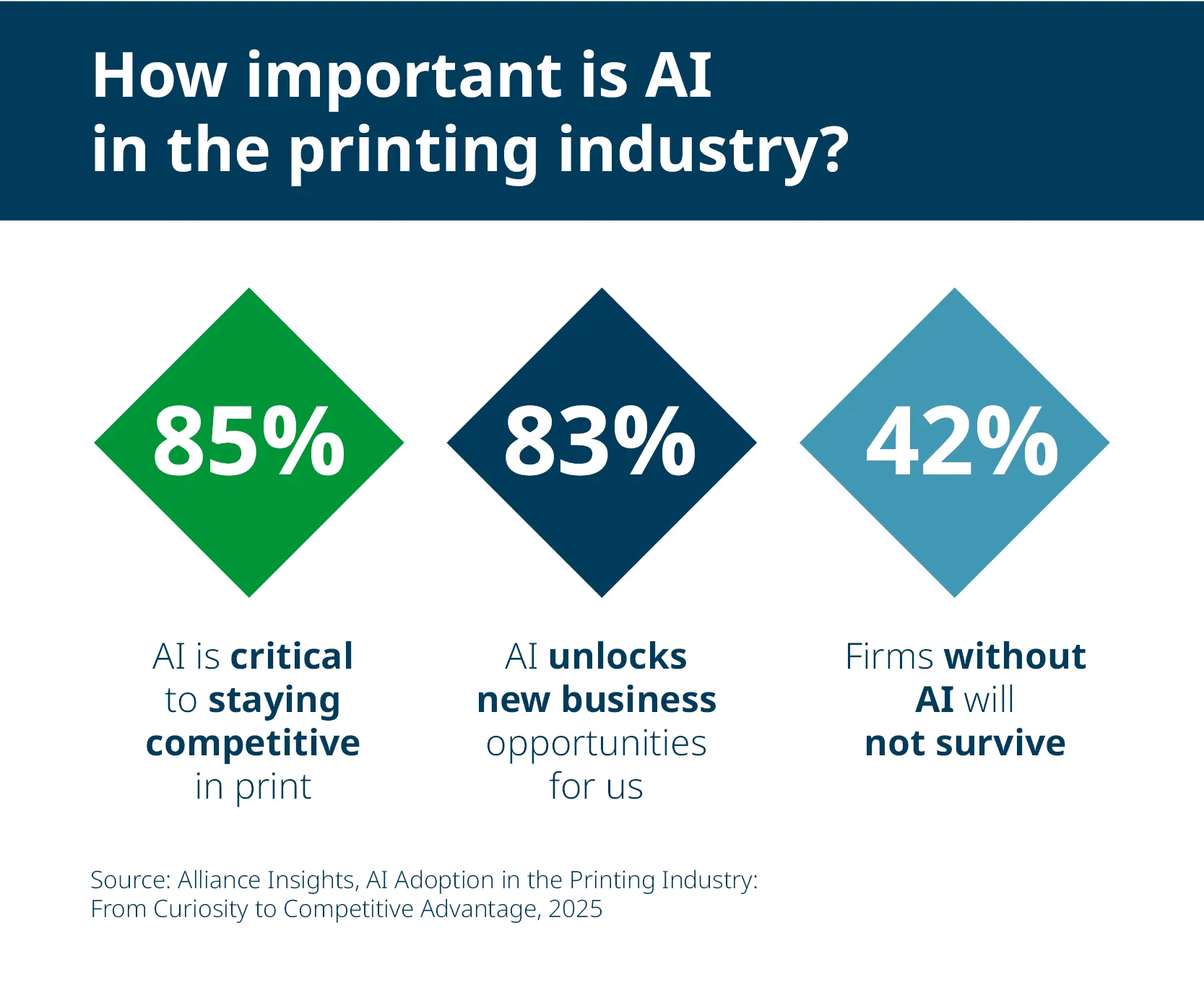

According to Alliance Insights’ “AI Adoption in the Print Industry”1 report, 85% of US print providers see AI as critical for competitiveness, leading many print businesses to take their first steps into AI in everyday operations. Many of them (42%), however, remain unsure where to start.

This blog examines how AI is being used in label and packaging businesses today and outlines how to address common challenges when preparing for long-term AI success.

The current state of AI in printing

Many print service providers have taken their first steps into AI adoption: more than half now complement human design skills with generative AI tools, and more than a quarter enhance customer support functions with chatbots or virtual assistants1. The result: enhanced accuracy, productivity, and speed.

Conversely, few converters report implementing AI tools on the shopfloor, with only 1 in 5 companies stating they currently use AI to enhance print and workflow processes1. However, some may not realise they have been using AI all along – in the guise of machine learning-based intelligent automation.

Many modern press workflows can now automate repetitive pre-press tasks, scheduling, and job routing. This improves operational efficiency while freeing operators to focus on more value-adding duties. Intelligent automation is also present in layout optimisation and colour management modules, while AI-powered, real-time RIP enables variable-data personalisation at scale without slowing production.

Only 1 in 10 converters claims to use AI-driven visual quality inspection to detect errors before they affect output, benefiting from less waste, fewer reprints, and greater reliability, with a similar number utilising predictive maintenance prompts1 – a number expected to grow rapidly as adoption continues.

Preparing for AI – overcoming the challenges

AI is not a single, ready-made solution that delivers instant results, but rather a set of specialised tools and systems that require specific conditions to deliver maximum benefit to converters. Many businesses face data quality, technological, and operational challenges during implementation, so anticipating and addressing these challenges can help set clear expectations and build a solid foundation for AI success.

Below, we outline the most common challenges converters face – and the practical steps you can take to overcome them.

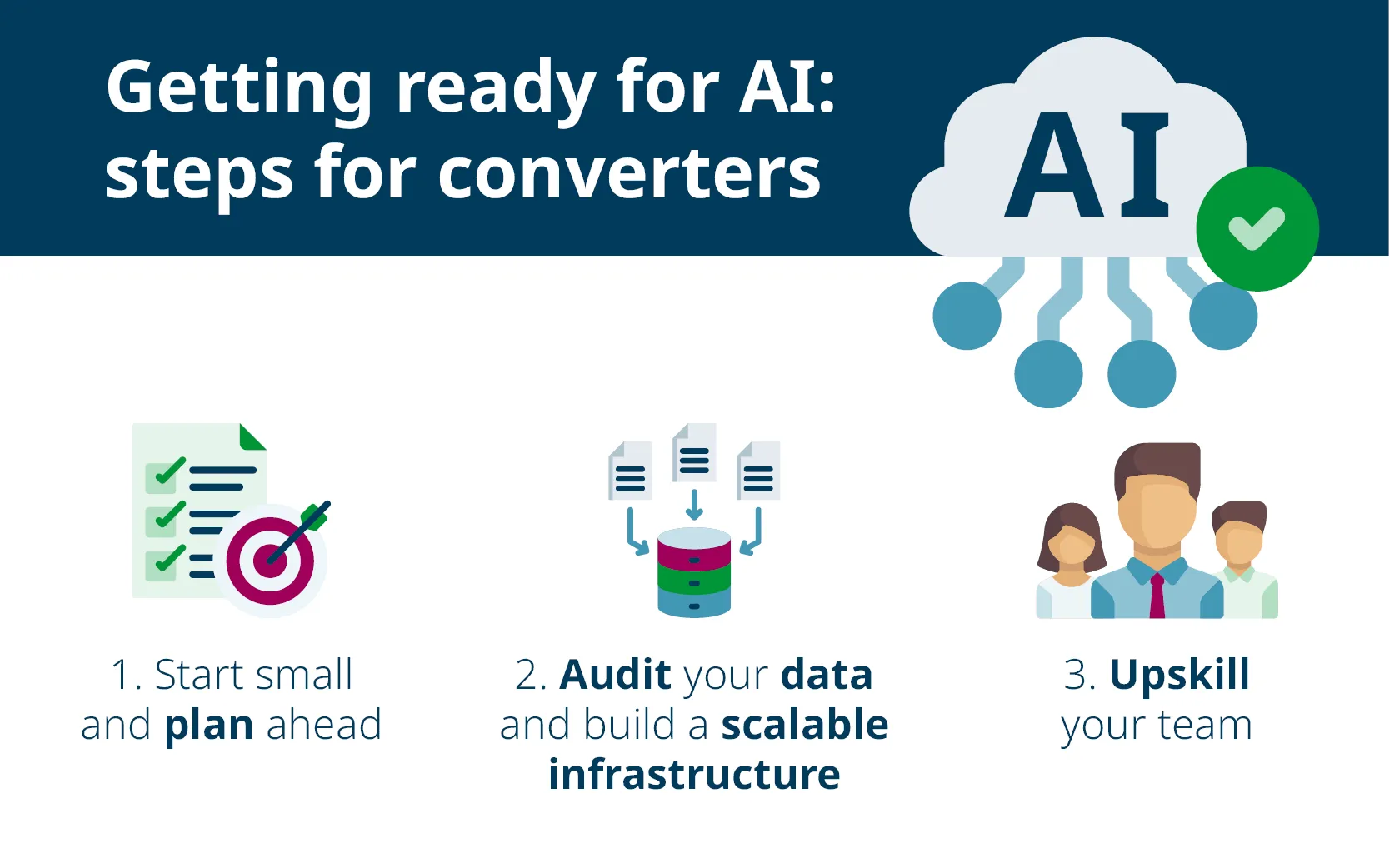

- Lack of coordination: Start small and plan ahead

In many businesses, AI adoption is not a coordinated effort; instead, a few individuals or departments experiment with one or multiple tools1. This approach, however, is unlikely to unlock wider-reaching benefits for business operations. Planning and coordination can pay dividends, creating a data-driven ecosystem where every stage of the customer journey and printing process is optimised for speed, accuracy, and sustainability – with real-time insights to support smarter decisions.

Considering where AI could add the most value is a great starting point. Focus on one AI use case, such as automating pre-press tasks, before scaling across the business.

- Data quality issues: Audit your data and build a scalable infrastructure

AI relies on clean, accessible, well-structured data to deliver valuable, actionable insights. By analysing data from print production equipment and ERP systems, AI can help identify customer order cycles, assess ink and substrate reorder patterns, monitor equipment efficiency and maintenance intervals, and more.

Because of the key role of data, it is important to assess the data management capabilities of current systems. Some systems may already feature data capture and intelligent automation tools. To maximise the benefits of AI, any new printing and ancillary equipment should be data-rich, offering strong, future-proof data capture and reporting capabilities to feed machine learning and AI models.

- Lack of expertise: Upskill your team

Having the right personnel to drive this business transformation is key to successful adoption, as a lack of expertise is often cited as a barrier1. Getting used to any new technology can be daunting for staff, and converters should upskill their teams to manage AI tools effectively. Targeted staff training will help build confidence in the technology and how it will enhance their skills while helping them manage their workload. 23% of print businesses are actively hiring for AI skills1.

Humans will continue to play a key role in AI-enabled print operations. In fact, leaders in AI adoption actively maintain human oversight of AI processes, with more than half (56%) of the print businesses surveyed ensure that human team members check and verify all AI functions1. While AI analysis can supply insights and predictions to support decision-making, humans are needed to interpret the results in the wider business context and take action.

The future: connected factories

Looking ahead, AI will continue to develop, creating faster, smarter, and more efficient workflows that will drive the creation of connected factories. Press-agnostic data platforms will unlock insights across the business, from customer purchasing patterns and equipment utilisation to preventative maintenance and material use – all aimed at driving smarter business decisions.

Now is the time for converters to prepare by building data, connectivity, and skills, seeking expert advice, and working with their digital printing supplier to ensure they are well-positioned to future-proof their business and take full advantage of what AI has to offer.

Ready to take the next step? Explore our blog on smart workflows and discover how digital workflows can transform your operations.

1Alliance Insights, “AI Adoption in the Printing Industry: From Curiosity to Competitive Advantage," accessed on 18th December 2025.