In an ever-changing, globalised marketplace, you need to be able to rely on your technology to not just deliver on your customer’s demands for today, but tomorrow and onwards as well. This places a strain not just on the individuals making those decisions on where, what and when to invest but also on the technology to scale according to the business’s needs. How is Continuous Ink Jet [CIJ] keeping up with the needs of today and tomorrow? Find out below.

While Continuous Ink Jet [CIJ] printing has been the poster child for coding technology, with a significant market share and large user-base. Despite this, however, the technology has not been the focus of significant innovation for some time. Meanwhile, advances in manufacturing environments have delivered significant improvements across the board.

In globalised industries, in which millions of products are moved every year, quality coding is critical for businesses and their supply chain alike. Poor quality codes have significant ramifications. Due to a lack of innovation, CIJ has arguably failed to keep pace with the industries it supplies.

To cover all the challenges affecting CIJ today, this blog post would turn into an epic novel. However, some of the main challenges affecting CIJ today include:

- Globalised markets create an increased need for traceability and anti-counterfeiting

- Consumer expectations and legislation are increasing the demand for detailed product information on packaging

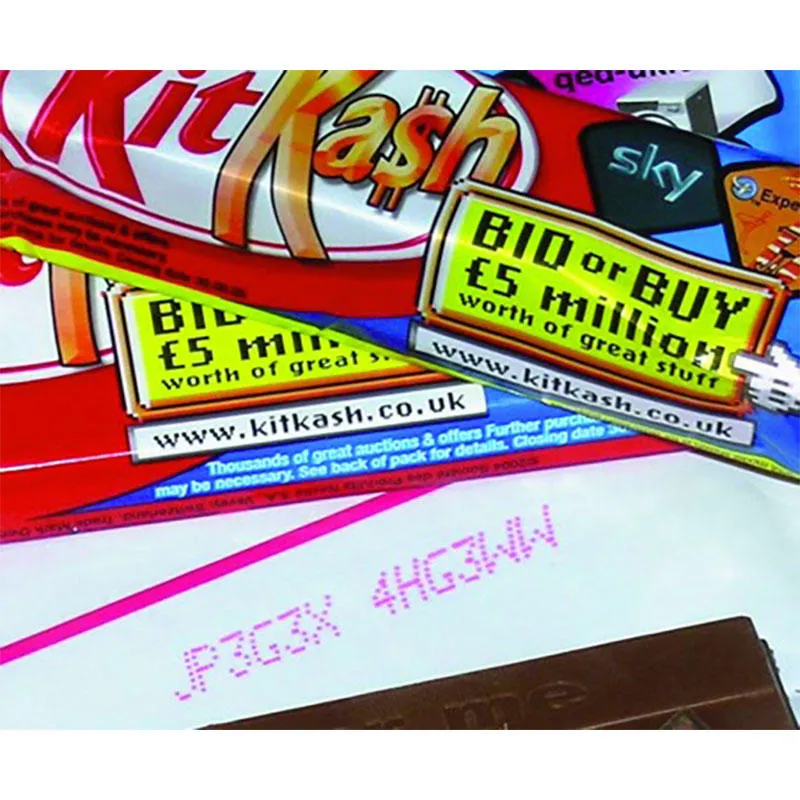

- Inter-brand competition fuels creative on-pack promotion, much of which uses codes as part of multichannel campaign activation.

>> Common print quality faults: how to identify and avoid them

Traceability involves marking stock in a way that allows items to be tracked through complex inter-connected systems, from production through distribution to the point of consumption. The implementation of a coding system is proven to be an effective tool for manufacturers and retailers maximising productivity and optimising supply chain management.

An additional challenge is the consumer’s escalating demand for transparency and exhaustive product information, which is increasingly backed by legislation. For example, many consumer goods must now display allergen and product origination data, requiring yet more information to be printed clearly and legibly onto a small printable area.

On-shelf promotion is a growing area of brand marketing, often as part of closely integrated multichannel campaigns that make use of variable 2D matrix codes – QR codes – to drive consumers to campaign-specific web landing pages. These codes require a level of precision that can be read by a smartphone camera, historically a challenge for CIJ.

In some industries, there is a particular need for ultra-accurate coding placement. For example, electronics are becoming smaller, meaning that codes too must become smaller and more precise. For instance, there are 1200 parts in a typical mobile phone, each one with its own individual code so that they can all be traced back to manufacture. For CIJ this can prove to be challenging, needing to code numerous individual components.

For a further in-depth look at how CIJ is changing to meet the needs of manufacturers and producers globally, be sure to check out our white paper Rewriting the Rules: How Continuous Ink Jet is changing to meet the future needs of manufacturing and our new Ax-Series website to find out exactly how Domino are rewriting the rules on coding and marking.

What did you think about this blog post? Let us know in the comments below, or find us on Twitter and LinkedIn. Be sure to follow the Domino Blog to stay up-to-date for the latest from Domino on products, industry trends, and advice for the future.