What if you could code onto both sides of the crimp on tube packaging at the same time, using just one laser? Domino has created the technology to make it happen. It makes tube coding easier, faster, potentially cheaper and - in summary - smarter than ever before.

From toothpaste to tomato purée, squeezable tubes are big business when it comes to consumer packaging. In fact, the tube packaging market size is estimated to grow from $6.65 Billion in 2016 to $9.30 Billion by 2021. The humble tube is used for everything from eye drops to glue; from shoe polish to shampoo. But nowhere is tube packaging used more prevalently than the cosmetics sector, which accounts for 65% of the world’s squeezable tube production.

Make no mistake: tube packaging is popular. But it’s a medium that presents coding and marking challenges.

Printing onto squeezable tubes isn’t easy

Like all other types of consumer packaging, squeezable tubes are required to carry certain codes or marks such as lot number, expiry date, serialisation codes and eye marks - the latter of which were recently at the centre of an inaccurate toothpaste-based conspiracy theory. There is a general trend in the packaging industry to code more production related data onto the product. This data at times is coded onto the crimp at the reverse end of the tube. In such scenarios and applications, space is at a premium, especially when coding tubes that are particularly small.

To tackle this issue some manufacturers choose to code on both sides of the crimp. That has traditionally required the use of two separate laser coders on the production line. Now a new innovation from Domino is here to change that - making dual-side tube coding more efficient and cost-effective than ever before.

Introducing Domino’s Tube Coding Module

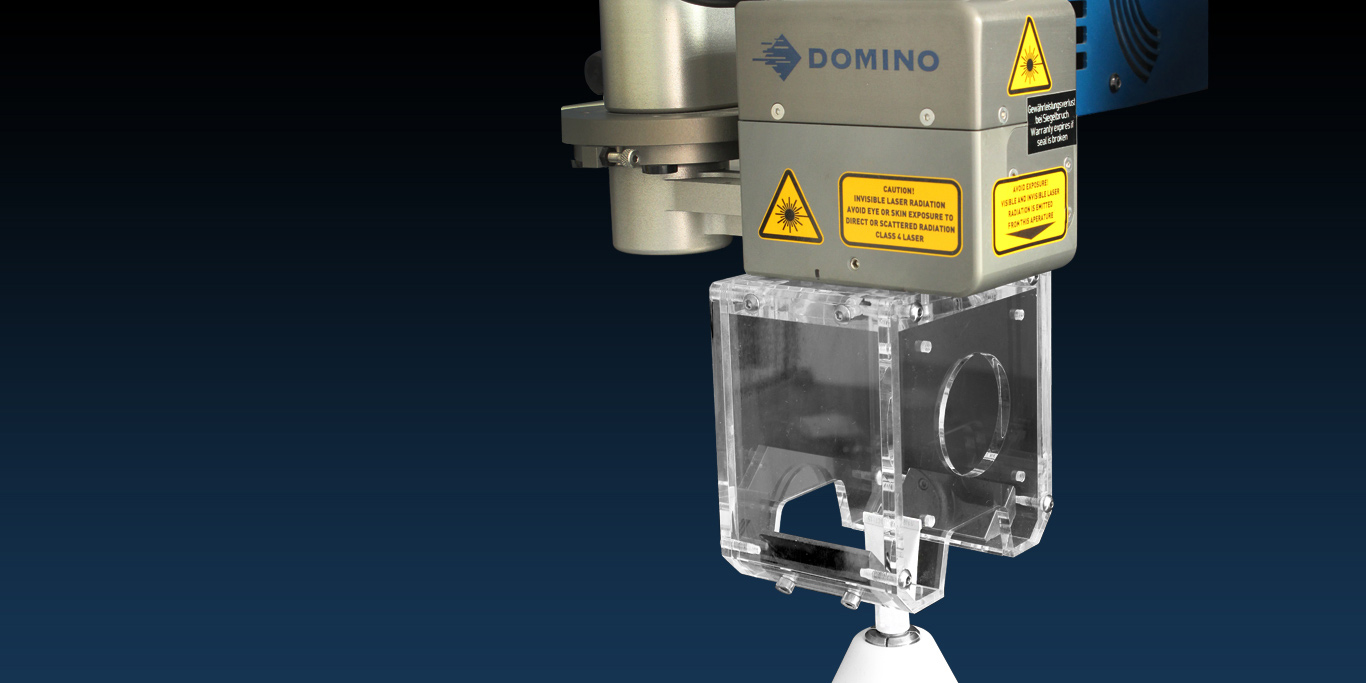

Domino’s Tube Coding Module allows you to code onto both sides of the crimp simultaneously - with just one laser. Not using two lasers naturally means decreased capital spend associated with buying a second whole new laser coder. It’s a cost-effective, fast and elegant way to double the amount of data you can add to tube packaging - whether you want barcodes, best before dates or promotional codes. Domino has designed the tube coding module to be compact and easy to integrate into squeeze tube production lines.

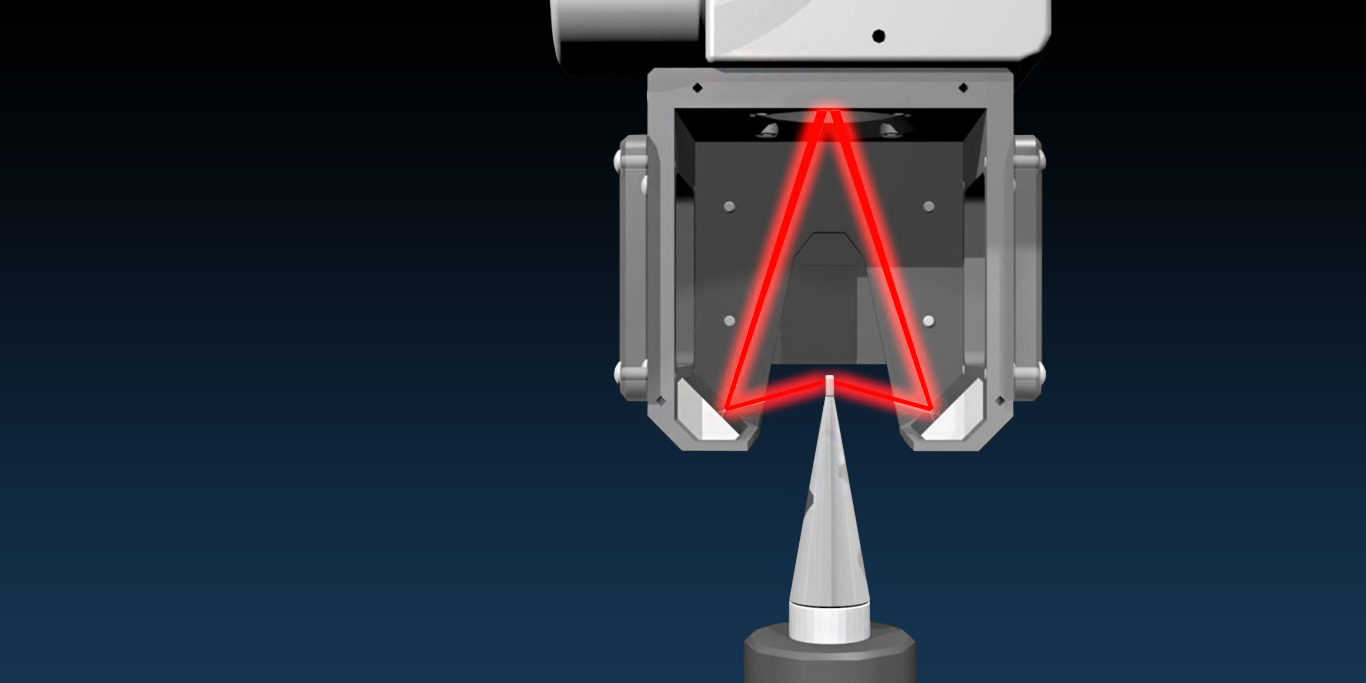

Sounds good so far. But how does it work? Our innovative tube coding module is an external module that attaches to the scan head of a Domino laser coder. Two mirrors deflect the laser beam exiting the scanner’s lens to allow you to code simultaneously on both sides of the crimp. The module also features a viewing window for production line operatives, all the safety features you should demand and comply to, as well as a connection for fume extraction. Safe, ingeniously simple, cost-mitigating and highly effective.

The Tube Coding Module is even extendable so that two or more tubes can be coded.

Of course let’s not forget the benefits of coding with lasers. Code quality and readability is high, with vector fonts instead of dot fonts and support for Chinese and Arabic characters. The code has high permanence with no wipe away issues. And laser is capable of handling variable data at speed from one tube to the next. A precise application for coding onto the tube crimp.

Want to know more?

Domino’s tube coding module potentially brings more speed, flexibility and freedom to dual-side tube coding. If you would like to know more about how it can enhance your tube coding operations, please get in touch.

You may also be interested in:

>> What are the best technologies for coding onto flexible packaging?

>> Keeping your staff safe when coding with lasers

>> How laser technology can simplify resealable and easy-open packaging production