Manufacturing and coding on face masks

Face coverings, surgical masks, cloth face masks, community-made masks, medical-grade face masks, respirators, FFP masks – all these different terms have now become an integral part of our daily vocabulary, and all in pursuit of a single goal: to slow down and help stop the spread of coronavirus.

The COVID-19 pandemic has seen demand skyrocket for face masks that protect people, leaving manufacturers scarcely able to keep up. It is safe to say that demand will likely remain high even in the longer term, falling only to a limited extent – this is because of the profound change in health awareness as a result of COVID-19. Companies are faced with major challenges and a large number of them need to adapt to new circumstances, breaking new ground.

For many, it is an opportunity for an overhaul and to respond to new growth in demand. Companies that may have operated in different fields are now producing medical-grade face masks to tap into market growth in this area. Yet manufacturing and coding onto face masks means considering many factors which, if not handled appropriately, could compromise plans to offer them on the market.

So, what are the important elements to consider in terms of legal coding requirements when manufacturing face masks?

Face coverings, medical-grade face masks, respirators – what’s the difference?

In order to determine which legal requirements apply when coding onto face masks and bringing them to the market, you must first clearly define what you are planning to manufacture.

Distinctions are made between:

Face coverings (community-made and single use masks):

Face coverings include home-sewn, reusable masks that help prevent the spread of the virus, thereby reducing the likelihood of transmission. These primarily protect others by stopping droplets from passing on to them, and are primarily intended for private, everyday use. It is important to know that these do not provide any protective barrier, and must not be advertised as protective face masks – they are therefore not subject to any coding requirements.

Single use masks, which are similar in appearance to surgical masks, again do not offer a protective barrier and therefore, cannot be advertised as a protective mask. Manufactures of these single use variants are required to either label or code the packaging.

2. Medical-grade face masks (surgical masks):

Medical-grade face masks include the familiar surgical masks primarily used in hospitals and doctor’s surgeries. They are mainly intended to protect others by preventing the spread of droplets from the wearer’s mouth and nose. Their main characteristic is that they protect the patient and people around the wearer. Medical-grade face masks are considered Class 1 medical devices and are therefore subject to the EU Medical Device Regulation 2017/745 (MDR).

3. Respirators (particle-filtering half masks and FFP masks):

Filtering facepiece (FFP) masks are mostly used to protect the wearer and work by filtering harmful substances and viruses from the air they breathe in. Depending on the respiratory filter used, a respirator can protect both the wearer and others. These masks are categorised as FFP1, FFP2 or FFP3 based on the filter performance. Respirators are a form of personal protection equipment (PPE) and are therefore subject to the legal requirements of the EU PPE Regulation 2016/425.

Coding requirements for medical-grade face masks

All newly manufactured face masks must meet the requirements of the MDR from 26.05.2021. Up to this deadline, the current legal requirements indicate that medical-grade face masks or their packaging must receive a CE mark after a conformity assessment procedure confirms compliance with DIN EN 14683.

On May 26.05.2025, only face masks that meet the legal coding requirements of the Medical Device Regulation may be placed on the market, regardless of the date of manufacture. For medical-grade face masks, this means that initially only the packaging needs to be coded in accordance with MDR. Medical-grade face masks will need to be coded directly from 26.05.2027 if they are intended for multiple use.

In order to avoid consequential costs, it makes sense to prepare now and set up the framework conditions for compliance. If you wish to market surgical masks, i.e., medical devices, you will also need to register as a medical device manufacturer.

See our MDR Guide for further information about the requirements of the Medical Device Regulation.

Coding requirements for respirators

When manufacturing particle-filtering half masks, also known as FFP masks, you must meet the requirements of the EU PPE Regulation (2016/425) and particle filter standard EN 149. As part of personal protection equipment, they provide protection for the wearer and others, depending on the filter. In countries such as the UK and the USA, this kind of mask also refers to the familiar N95 masks, named for the fact that they filter out at least 95% of tested microparticles.

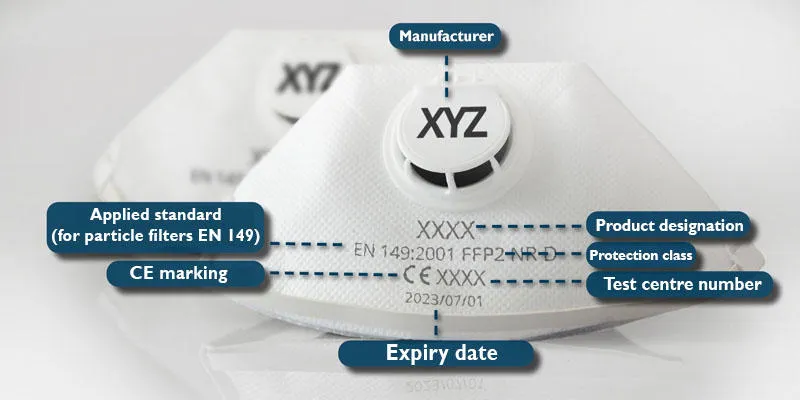

These masks must be coded with the following, in a permanent, easily legible and visible manner:

- Manufacturer name

- Product designation

- Applied standard

- Protection class (FFP1, FFP2 or FFP3)

- Indicate whether it is reusable (R) or for single use (NR = Non-Reusable)

- A reusable respirator must also undergo dolomite dust testing and then be marked with an additional ‘D’ to indicate this. If the mask is non-reusable, this test and further coding is optional.

- CE marking with the corresponding test centre number

- Expiry date

What you need to know when manufacturing and coding respirators

Respirators must undergo a type test according to the appropriate standard, conducted by a testing and certification centre. In addition, a conformity declaration must be produced according to the applicable standards. If you are planning to market FFP masks as medical devices that are subject to the PPE Regulation, the respirators will also be subject to the Medical Device Regulation.

You need to ask yourself a central question:

What is the purpose of the mask?

Your answer to this question will inform you of the applicable coding requirements . If the mask is intended to protect the user, then the requirements of the PPE regulation must be implemented. This includes for example, the FFP masks, as they contribute to the personal protection of the user. However, if the mask is used to protect the patient, then the Medical Device Regulation will apply to all newly manufactured face masks from 26.05.2021.

Trust in the expertise of our Domino experts

As a partner of many years to numerous medical device and PPE manufacturers, our sector team are on hand with help and advice so you can determine and apply the right coding solution for your production situation. We understand the potential pitfalls and focus on finding a solution that is adapted to your needs. Our portfolio in the most varied of coding technologies means we can offer you the technology best suited to you, enabling you to comply with the legal coding requirements for medical-grade masks. Domino is a member of the European Printing Ink Association (EuPIA) and develops its own inks manufactured according to Good Manufacturing Practice (GMP).