When printing in cable, wire, and extrusion applications, you need a coding solution that can print product information, logos, and product length markings that withstand production processes and shipment to end users, especially when coiled onto drums.

Domino’s Continuous Inkjet (CIJ) and laser technologies will meet your coding needs. All are designed to minimise impact on production throughput when coding onto power cables, communication cables or special cables. With reliability built-in as standard, our customizable solutions provide high-quality coding and help to ensure adherence to regulatory compliance in the cable and wire industry.

Ink-based systems

Domino's Ax-Series Continuous Inkjet (CIJ) printers provide printed code adhesion that is resistant to water, solvents, and scratches, with non-offset properties to ensure code clarity throughout the product’s life. No matter if you need to print single and multi-line codes, symbols, company logos, meter and inch markings, version and type designations, test numbers or 1- and 2D codes, with Domino’s Ax-Series Extrusion Printer we cover them all.

Our range of inks provides excellent code contrast on both dark and light surfaces, with fast-drying characteristics to meet the diverse application needs when coding on cable and wire sheathing and extruded industrial products. The flexible print formats allow for high-quality printed codes over a range of different print heights within a single code, and font matrix of up to 32-point size.

The enhanced software in our Ax-Series printers ensures easy setup and accurate messaging repeats, with the ability to code at print rates greater than 150 per second. Compared to traditional coding methods, our Ax-Series CIJ printers offer flexible printing, higher throughput, and quicker job changes without interrupting the production line. The devices are also designed so that you can connect them to all leading extrusion systems and cable processing machines.

Extrusion Ink Coding Station

For extrusion lines offering pre-treatment

Are your materials particularly difficult to print on (e.g. polymeric cable insulation, PE, PP and PTFE)? Learn more about our Extrusion Ink Coding Station (EICS), requiring plasma or corona pre-treatment, which provides you the optimal print adhesion on your product. The EICS includes our Ax-Series Continuous InkJet (CIJ) Printer, as well as an innovative guidance system for ideal product handling.

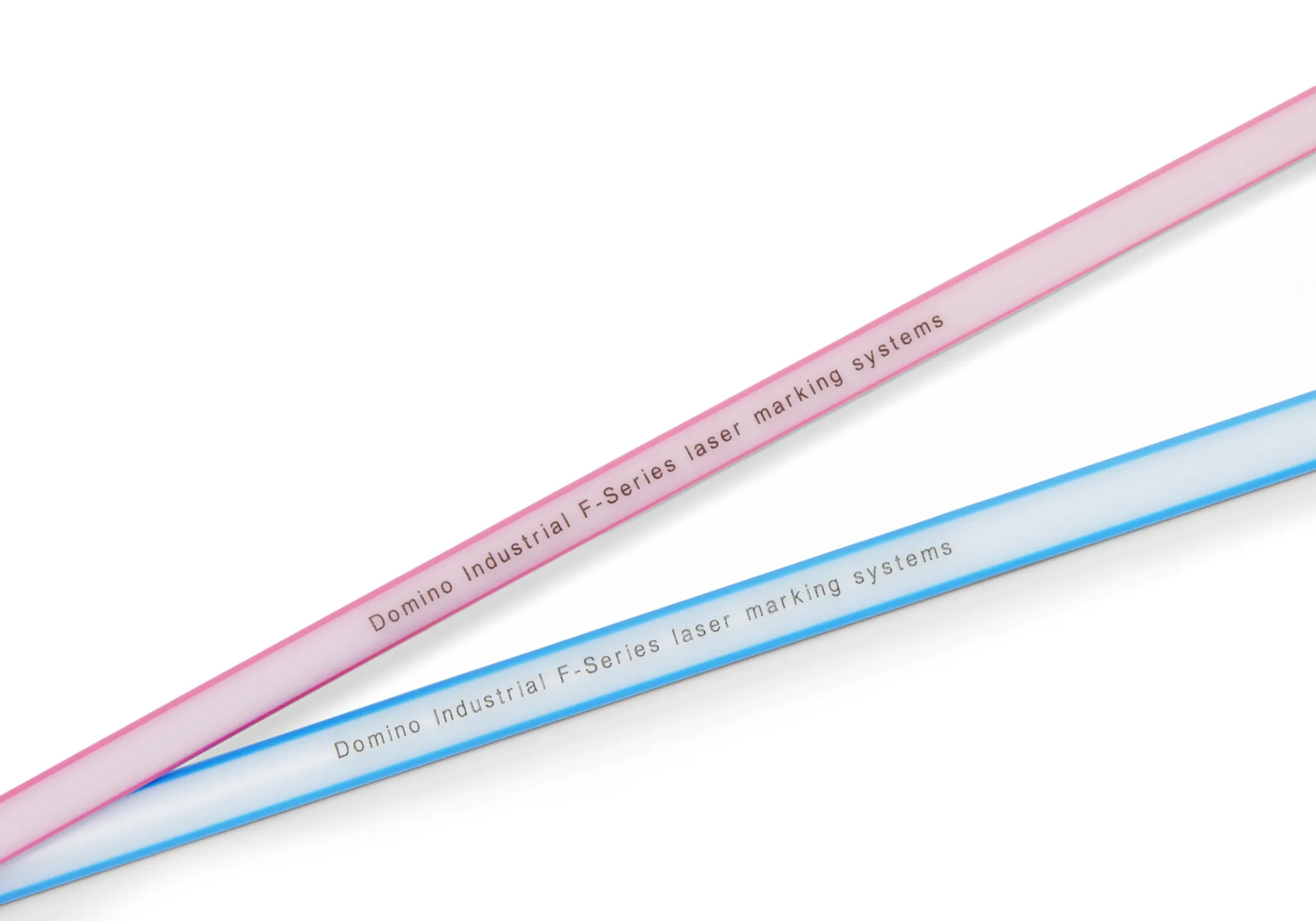

Laser coding systems

Our CO2, fiber and UV lasers create permanent human and machine readable codes. Providing excellent legibility lasting the lifetime of cables and wires, they are an ideal solution for products with long and complex supply chains or requiring durability in challenging environments.

Domino’s laser coders are optimized for high-speed markings, graphics, logos, standard industrial 1D, 2D machine readable codes and support traceability with serialisation data, sequential and batch numbering. We offer bespoke customization and integration into ERP, WMS and MES systems.

The three key laser technologies – CO2, UV, and fiber – offer coding on dark plastic materials and plastics with additives, as well as being ideal for PVC sheathed cables, therefore delivering superior coding on plastic substrates.

The ideal configuration depends on the specifics of each application. Our laser specialists are on hand to test your substrate and help define the ideal solution. When operating laser systems, safety is paramount: laser guarding, extraction to remove particles that can damage equipment and reduce code quality, correct installation, prevention of access in operation – we have you covered.

Extrusion Laser Coding Station

For continuous applications

In compliance with laser class 1, the innovative Extrusion Laser Coding Station (ELCS) can include a CO2, fiber, or UV laser. Additionally the ELCS includes a product guidance system combined with length measurement to enable a worry-free knot transfer up to diameters of 50mm at speeds of up to 500m/min.