Can you afford to miss the opportunity?

In the recently published White Paper ‘When does inkjet postprint pay for converters’, Print & Packaging Analyst & Consultant Dr Sean Smyth provides an insight into the growing success of inkjet technology in the corrugated packaging sector.

The demand for corrugated packaging is growing worldwide, and single-pass digital inkjet is by far the fastest growing print technology serving this thriving sector. As the market expands, new inkjet press installations are facilitating exciting opportunities for corrugated converters. Not only is inkjet enabling them to meet the increasing demands of customers, its versatility is also helping converters to open up exciting new business opportunities and increase profit margins.

What's behind the growth in the corrugated sector?

- E-commerce: The e-commerce sector continues to fuel the demand for cost-effective secondary packaging solutions.

- Sustainability: Corrugated board is the ideal sustainable packaging solution for brands and retailers looking to meet environmental obligations and deliver a more eco-friendly product to their consumers.

- Need for speed: As the instant-gratification demands of consumers continues to increase, speed to market is evermore important. The use of inkjet in corrugated print applications allows businesses to respond more quickly to their customers’ requirements. This is because the need to make and load flexo plates, often supplied by a trade repro house platemaker, is eliminated and this ultimately saves time.

- In-store presence: More corrugated packaging is now consumer facing, in-store – Secondary packaging, previously a plain cardboard container for delivery & storage, has a ‘direct-to-shelf’ role requiring a high-impact visual on-shelf presence.

- New print technologies: The expanding capabilities of digital inkjet print technology is revolutionising the capability of corrugated converters to deliver quality print, impactful visuals and branded graphics, transforming the plain cardboard box into a high value packaging solution.

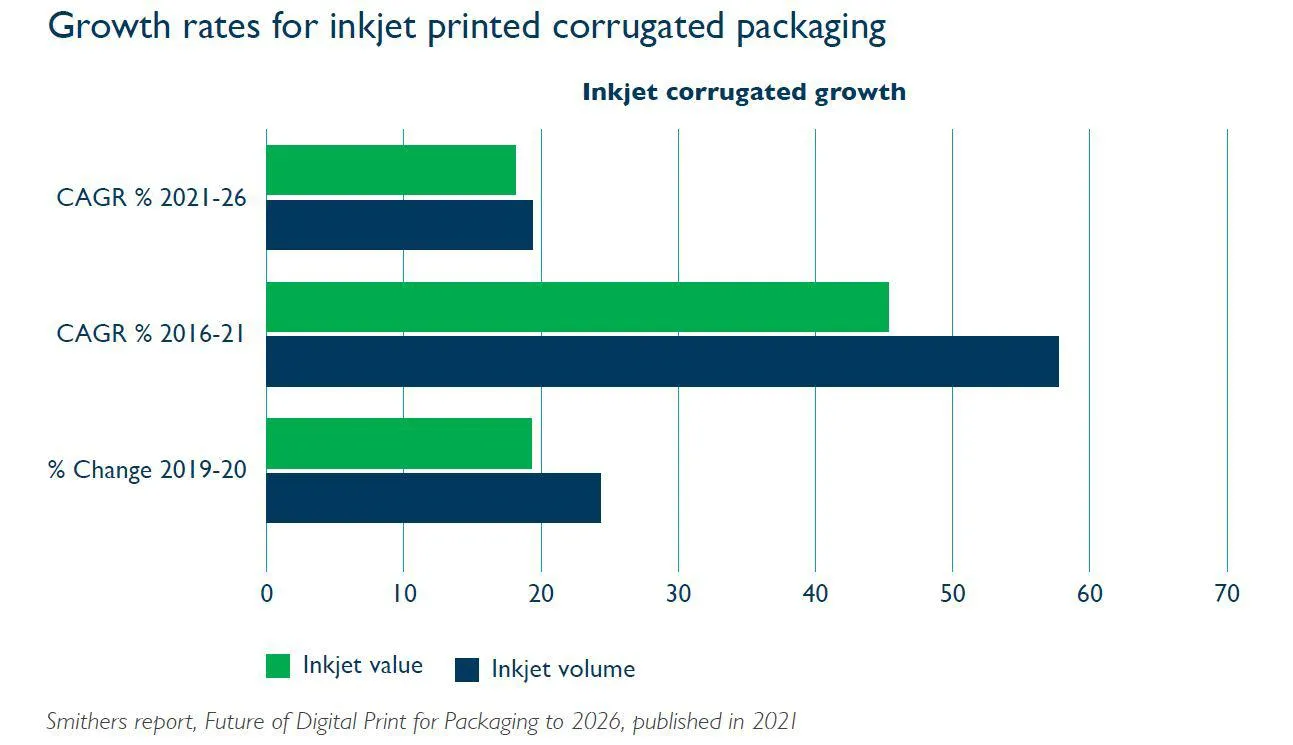

According to ‘The future of Digital Print for packaging to 2026’ published by market research company Smithers, the volume of digital inkjet in corrugated packaging grew by over 57% annually from 2016 to 2021, and by more than 45% in terms of value.

This clearly demonstrates the high-value opportunity inkjet offers converters, and early inkjet adopters are already reaping the rewards.

Digital inkjet offers a win-win for both converters and customers

|

What Inkjet offers

|

The Benefits

|

|

Removal of costly and time-consuming flexo platemaking

|

Quicker response to customer orders and increased profit margins

|

|

Instant print output

|

Quick turnaround times/response to customer demands

Customer satisfaction is increased

|

|

Printing of high quality colour graphics

|

High impact presence for in-store branding

|

|

External and internal print capability

|

Higher perceived value and boosts unboxing experience for customer

|

|

Potential for personalisation/versioning

|

Boosts unboxing experience for customer

|

|

Converting plain packaging into high value packaging

|

Greater profit margins

Improved customer satisfaction

|

|

Flexible print output volume

|

Opportunity to secure new contracts

|

|

Shorter, cost-efficient print-runs

|

Cost-effective personalisation and versioning

|

|

Print-on-demand capability

|

Reduced stock inventory

Less waste through product obsolescence

|

|

Quicker response times

|

Greater flexibility to capture new jobs

Customer satisfaction is increased

|

Converter Benefits

Finn MacDonald, President of corrugated packaging solutions firm Independent II, is the first user of the Domino X630i in the US.

Speaking about the benefits the revolutionary printer brings to his business, MacDonald says:

"It takes one to three business days to receive and mount flexo plates, and over 15 days to source and laminate litho sheets. With inkjet it is incredibly easy to produce jobs with multiple versions. There is both demand and there is plenty of room to educate and inspire the Customer to consider versioning. The visual and functional benefits of versioning and digital flexibility are dynamic to say the least. Customers who benefit from this are Customers for Life."

Finn MacDonald, President of Independent II

Download White Paper

To find out more about the potential of inkjet within the corrugated packaging sector, and to learn how it can enhance your converting business, read Dr Sean Smyth’s white paper ‘When does inkjet postprint pay for converters’

Dr Sean Smyth has spent more than 30 years in senior technology posts for a variety of print and packaging businesses across the supply chain. He now acts as an analyst and consultant in print and packaging for businesses wanting to benefit as the world digitises. He is a “Print techie”, helping companies across the supply chain make money through appropriate use of technology in changing markets.

In addition, Sean is a regular speaker and Chair at international printing technology conferences and events, and writes for companies and the trade press in the UK and North America.