Underground criminals producing counterfeit goods have become alarmingly good at replicating manufacturers’ branding and are infiltrating the market. That’s a huge problem for both manufacturers and consumers.

Counterfeit products can present terrifying dangers. These falsified products are then made to look authentic thanks to replicated labelling that appears almost indecipherable to the branding of genuine products.

The scale of the problem is huge.

Recently, in China 50 factories were caught making counterfeit seasoning being designed to look like a very well recognised brand. Some of the packs being produced included hazardous chemicals such as nitrite and heavy metals which could cause harm to the kidney and liver. It’s important that brands look after their customers and come together to fight these counterfeit criminals.

In January 2016 Italian authorities seized 9,000 bottles of fake champagne, along with 40,000 labels imitating the house’s branding. These tainted bottles can be life threatening. Unfortunately, a family lost their 20-year-old daughter from drinking counterfeit alcohol whilst on holiday in Mexico earlier on this year. This heartbreaking news is something that sparked conversation and has raised concern amongst many.

Along with food and alcohol there are many other industries vulnerable to imitation. Approximately, 62% of medicines bought online are illegal, according to European Alliance for Access to Safe Medicines. This figure is consistently growing at a scary rate, this means that brands need to think fast and tackle the issue.

What can brands do in response?

A sophisticated problem requires a sophisticated resolution. The good news is that the technology is out there to help manufacturers tackle the challenges posed by counterfeiters.

Traceability coding

Battling counterfeit criminals depends on efficient coding and marking of your product and packaging at every stage in the supply chain; resilient coding that can be read by all parties. Modern coding technology makes it easy to apply traceability codes onto a huge range of materials - such as, plastics, glass, films and foils - without delaying the production speeds that are so vital to your bottom line.

Secondary packaging

POS packaging is often used to help a product stand out on the supermarket shelf. But could it also help tackle counterfeit crime? Perhaps. Counterfeit criminals are unlikely to replicate secondary or tertiary packaging as well as a drink’s primary labelling. It means secondary packaging is not just a vehicle for asserting brand identity, but a means of reassuring the customer about product authenticity.

QR codes

Adding smartphone-readable codes to product packaging is cheap, easy and hassle-free. It also provides a vehicle for verifying the authenticity of your products. A simple scan with a smartphone could drive consumers to a website to prove the provenance of a product. To elaborate: while counterfeit criminals could easily add QR codes of their own to fake food products, they wouldn’t be able to create a coding system that indexed your products and drove consumers to your official website. That would require hacking your entire information infrastructure. As a secondary benefit, smartphone-readable codes give brands a new and highly personal way of building the relationship with customers.

>> Customer relationship codes

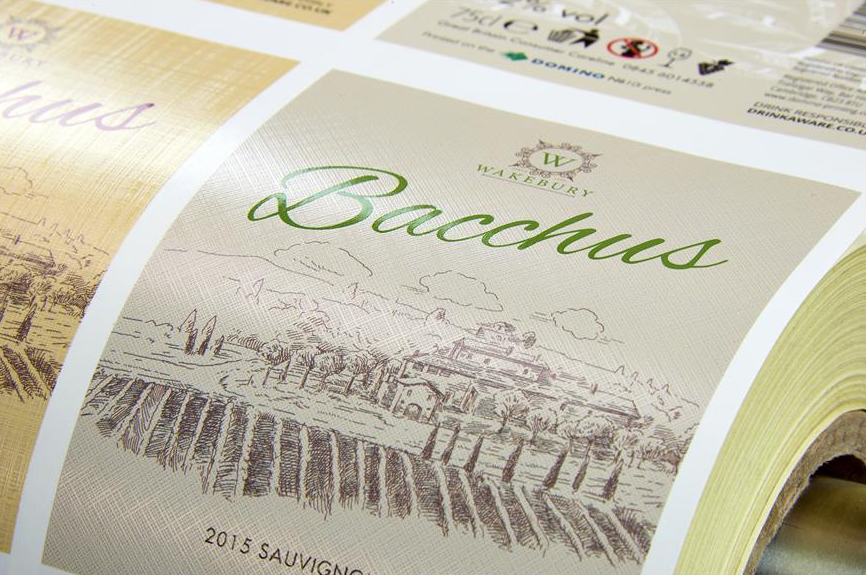

Textured labelling

The counterfeit problem is growing in severity principally due to technology that has made it cheaper and easier for criminals to replicate a manufacturer’s branded bottle labelling. A further barrier to imitation is to invest in premium labelling that is much harder for criminals to imitate convincingly, such as textured labelling.

>> Premium packaging: the benefits of textured labelling

Tamper-proof packaging

Tamper proof packaging is usually implemented on medical packaging, and similar techniques can be used to prevent tampering on food and beverage products. Global Closure Systems have created a bottle cap that prevents criminals refilling genuine bottles with fake contents. It’s all done thanks to a tamper-evidence ring that breaks off if forced removal is attempted.

We can help...

If you would like expert advice on safeguarding consumer safety as well as your brand and corporate reputation, get in touch. We have products and experience that can help tackle the counterfeit alcohol problem.