Why Aluminium Packaging and High-Speed Coding Are Leading the Beverage Sustainability Charge

What if the most powerful sustainability solution for beverage packaging was already in your hand?

Aluminium cans remain one of the most trusted solutions for sustainable beverage packaging, supported by well-established recycling systems in developed markets. Today, merging technologies are unlocking new levels of compliance and traceability – putting aluminium back in the spotlight as a key driver of circularity.

As beverage brands strive to meet circular economy targets and cut carbon emissions, aluminium’s recyclability and efficiency make it an obvious choice. But sustainability doesn’t stop at the can. Every stage of production matters, including the coding that underpins compliance and traceability at scale. New high-speed, low-waste technologies, such as fibre Laser coding, allow manufacturers to maintain sustainability without compromising performance throughput.

Why is Aluminium Considered the Circular Champion?

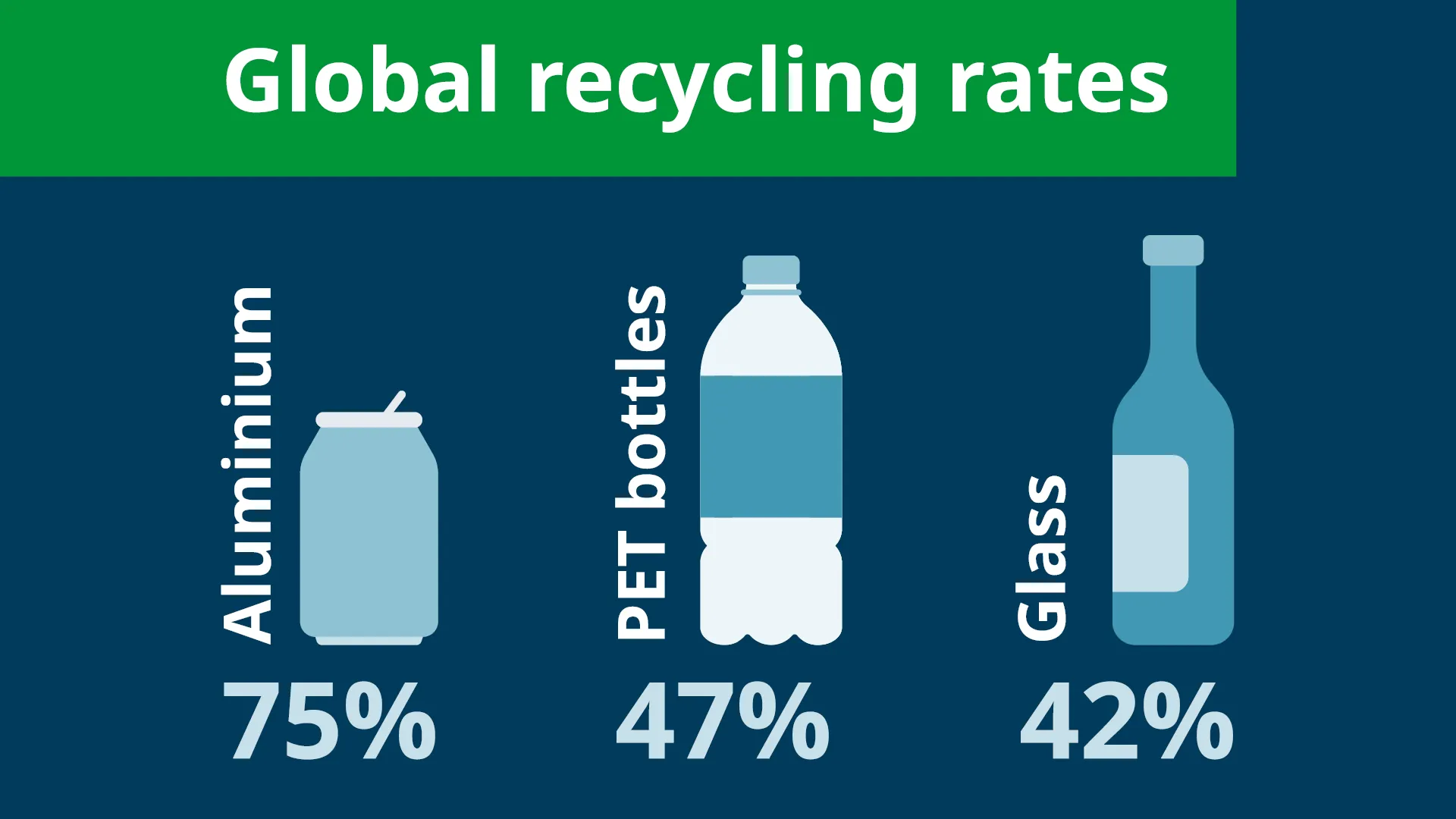

Aluminium is a true closed-loop material. Unlike PET or glass, it can be recycled infinitely without losing quality. Global aluminium recycling rates sit at around 75% – outperforming PET bottles (47%) and glass (42%) – which saves an estimated 5.4 million tonnes of CO₂ annually.

Within packaging, regulation is elevating aluminium’s importance. Under the EU Packaging and Packaging Waste Regulation (PPWR), aluminium packaging must meet 50% recycling by 2025 and 60% by 2030, alongside strict design-for-recyclability requirements. For beverage brands, aluminium isn’t just a packaging choice – it’s a compliance strategy and a reputational asset.

Why Does Speed and Accuracy Matter in Beverage Can Coding?

Modern beverage lines often exceed 120,000 cans per hour. At this pace, coding is mission-critical as any errors or issues become expensive very quickly: creating costly recalls, wasted product, and regulatory exposure. Every can must carry accurate traceability information to meet regulatory and retailer requirements.

Conventional inkjet systems can struggle at these speeds, introducing chemical waste and slowing production. The industry needs coding technology that matches fast-moving, sustainability-driven operations. In contrast, laser coders are proven to be the best coding solution for aluminium cans, offering exceptional reliability and consistency of performance – they’re so reliable that some customers forget they’re even there.

BECCS: High-Speed, Low-Waste Coding for Sustainable Beverage Packaging

Recent innovations are helping to reshape how beverage manufacturers approach both sustainability and compliance. One of the most significant is the Beverage Empty Can coding Systems (BECCS) – a purpose-built solution for high-output lines where accuracy, speed, and low waste are non-negotiable. By shifting coding upstream to the empty can stage, BECCS tackles two persistent challenges at once: reducing resource use and preventing costly downstream errors. Powered by fibre Laser technology, it produces permanent, high-resolution codes with no inks, solvents, or consumables – eliminating chemical waste and reducing operational overheads.

Why BECCS is leading the sustainability charge:

- Pre-Fill Coding Advantage: Errors are caught upstream before cans are filled, saving product, time, and money.

- Zero Consumables: No inks or solvents means no hazardous waste and lower carbon impact.

- High-Speed Performance: Matches line speeds of 120,000 cans per hour, ensuring coding keeps pace with production.

- Integrated Vision & Rejection: Real-time error detection prevents faulty codes from reaching the market, reducing waste and downtime.

- Minimal Maintenance: Fibre lasers offer up to 100,000 hours MTBF, cutting downtime and costs.

Beyond performance, BECCS enables brands to maintain production traceability and comply with EU labelling requirements, without sacrificing efficiency.

Closing the Loop

Aluminium cans and fibre laser coding create a powerful sustainability partnership. Together, they enable beverage brands to meet circular economy targets, reduce carbon emissions, and maintain production agility. As the industry moves toward 80% global aluminium recovery by 2030 and near-100% by 2050, technologies like BECCS will play a pivotal role in closing the loop – ensuring that every can is coded accurately, efficiently, and with minimal environmental impact.

Key Takeaways

- Aluminium packaging is infinitely recyclable and meet EU circular packaging targets.

- High-speed coding is essential for compliance and efficiency.

- Domino’s BECCS system eliminates waste, reduces carbon impact, and supports sustainability goals.

Ready to Lead the Sustainability Charge?

Explore how Domino’s BECCS system can help your beverage brand achieve high-speed, low-waste coding and contribute to PPWR targets in beverage packaging.

Learn more about BECCS and fibre laser coding solutions