If you are looking to buy a batch coding machine, but overwhelmed by the wealth of technologies on offer, Domino is here to help. Read on to discover the most efficient and cost-effective solution for your company.

Choosing the correct batch coding machine is imperative to ensuring that products can move seamlessly through a supply chain. But with so many batch coding options available, it can be difficult to know which machine is best.

Different industries require batch coding machines capable of applying codes and data to a wide variety of products and packaging. Other variables, including production line speeds and factory environment, will also determine which machine is best for a given application.

In this post we will take you through details of all the different technologies on offer, and how these apply to different industries and products so that you can make an informed choice when choosing your batch coding machine.

The importance of batch coding

Whether you work in industrial and manufacturing applications, food and drink production, or the pharmaceutical or automotive industries, batch coding will feature as an integral part of your manufacturing process.

Batch codes are critical for traceability, enabling a product to be traced through all stages of production, processing, and distribution. Individual batch numbers are made up of a combination of different identifying codes, relating to the product, production line, production date, the time of production, and so on.

If a customer buys two identical products from a supermarket, they may have exactly the same ingredients, in exactly the same quantities, but if they were made on a different day, or on a different production line, or with ingredients sourced from a different supplier, they will have different batch codes.

These codes are vitally important for product recalls. If a consumer, retailer, or anyone further down the supply chain finds a problem with a product, the batch code allows the product to be traced back to the source. Products with the same batch code can then be withdrawn from sale at a reduced cost to the manufacturer. The larger a product’s batch, the more costly it is to facilitate a product recall.

Types of batch coding machine

Manual batch coding solutions

Manual batch coding machines are operated by hand and generally only suitable for very small production runs. Examples of these machines include traditional hot stamps, and ink pad, or sticker roller coding machines. This type of machine will typically be used by small manufacturers, producing a small range of products, often by hand and for limited distribution.

Semi-automatic batch coding solutions

Semi-automatic batch coding solutions are electronically driven, and apply codes automatically, but do not integrate onto automatic supply lines, meaning that product feeding and collection must be done by hand.

Automatic batch coding solutions

Automatic batch coding machines apply data to products as they run along a production line without the need for any operator intervention. Once an automatic batch coder is set up with the required code, product feeding and printing are carried out automatically until a change in product or code is required. Automatic batch coding solutions are the preferred choice for large scale production or automated production lines.

Contact or non-contact?

All batch coding machines, whether manual, semi-automatic, or automatic are further divided into two main categories – contact and non-contact. Whether you require a contact or non-contact batch coder will depend on your industry, and the type of product being produced.

Contact batch coding machines

Contact batch coding machines come into direct contact with the surface of the product or packaging being coded. Contact batch coding solutions include traditional rubber or metal stamps, as well as automatic thermal transfer overprinting (TTO) machines.

Non-contact batch coding machines

Non-contact batch coding machines do not physically meet the surface of the product being coded, and instead use techniques such as lasers and ink sprays to apply the desired code. Non-contact machines are good for batch codes which need to be changed frequently. Examples of non-contact batch coding solutions include continuous inkjet (CIJ) and thermal Inkjet (TIJ) printers, and laser coders.

Technologies

Thermal transfer overprinting

Domino’s V-Series range of thermal transfer overprinters can be used at high speeds to produce high-quality codes on flexible films and labels. TTO printing is a preferred technology for batch coding processed and convenience food, with printers integrated into packaging and processing equipment including tray sealers, flow wrappers, and baggers.

In a TTO solution, a code is transferred directly onto a product packaging or label, using heat applied to an ink ribbon in a specified target area, as such the print head must come into full contact with the print area in order to produce a code.

Continuous inkjet printing

Domino Printing’s Ax-Series of continuous inkjet printers are used in a variety of differenct industries, including food, beverage, and industrial and manufacturing sectors. Ax-Series printers are designed to withstand harsh conditions, and can print on a variety of surfaces, from thin plastic film to thick ridged metal.

Thermal inkjet printing

Domino Printing’s Gx-Series thermal Inkjet range of printers are non-contact ink coding machines that can achieve high-resolution printing, at very fast speeds. These are ideal for the mass coding of drug and medical devices with increasingly sophisticated codes and messages.

Laser coders

For some applications, a non-ink-based batch coder may present the best solution. For example, in the beverage sector, printing batch codes on the bottom of beer cans, wine bottles, and water bottles will require a system capable of printing on foil seals, PET, and glass, such as a scribing laser.

Such a solution can be found in Domino Printing’s range of durable D-Series CO2 lasers and F-Series fibre lasers – high-speed, harsh environment laser marking machines capable of coding onto a wide range of items and materials. This includes glass, plastic, foil, and metal.

Options for handling batch code information

Another important consideration when choosing a batch coding machine is how you would like to handle your data. There are various options available from manual data entry, through to full coding automation.

Manual data control

At entry-level, data can be entered directly onto a batch coding machine for printing onto a product or packaging. In such a scenario, an operative would be employed to enter all data onto a label design or code template. The machine would then print the code onto the product. Such a system can be susceptible to coding errors if an operative makes a mistake during data entry, which can necessitate product recalls.

Semi-automated control

Another option for manufacturers is semi-automated data control, where a batch coder can automatically populate a label or code template based on certain information. In such a scenario, an operative would be required to enter data from defined categories, for example, date, product code, line number, etc., into a piece of software that would then translate the data into final code for printing. Domino’s QuickStep user interface is provided with all Domino batch coding machines, enabling operatives to design labels and code structure, and automatically populate designs based on manually entered information.

Fully-automated data control

A more advanced solution for manufacturers comes in the form of a batch coding software that can integrate into an existing supply system to create batch numbers based on product data and automatically populate the label software. Domino’s QuickDesign coding automation and label design software enables all Domino printers to integrate into MES and ERP systems, to accurately collect and curate data and automatically switch messages. A coding automation system eliminates the need for human touch, resulting in fewer errors, less downtime, and greater operator capacity to carry out tasks elsewhere on the factory floor.

Major Industries and best suitable technologies

Different industries require different batch coding machines. The following sections highlight typical batch coding systems in some of our main industries. If your industry isn’t listed here, please get in touch for more information. You can also read more insight into the coding and marking technologies used in specific sectors in our blog.

Industrial and manufacturing

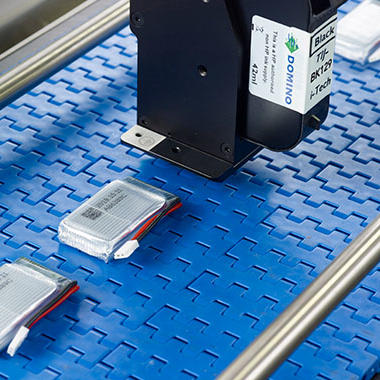

In the industrial and manufacturing sector, batch code printers may be used for a variety of different products with manufacturer-specific tracking and batch codes. This includes, but is not limited to, cable and wire, automotive and aerospace parts, and electronic components.

The nature of this industry can require the application of codes on curved or irregular surfaces, which can be achieved using non-contact industrial printer technology. Non-contact batch coding machines can also be used to replace complicated manual printing processes for speedier overall production.

Domino Printing’s Ax-Series of continuous inkjet printers have been made with industrial and manufacturing sector coding requirements in mind. Ax-Series printers are designed to withstand the harsh conditions often found in industrial production environments, while still being able to print on a variety of surfaces, including plasterboard, wood, and thick ridged metal.

Food and beverage

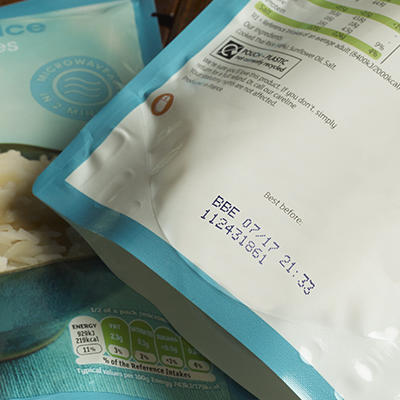

Batch codes are vital for those who manufacture and sell food and beverage products, as well as the retailers and end consumers that they supply. In the food and beverage industry, the type of machine needed can vary depending on the substrate being coded. This includes various substrates used for packaging food and drink products, or sometimes, as with the individual batch codes printed on eggs, the food itself.

Domino’s Ax-Series of continuous inkjet printers are an ideal print solution for batch coding a variety of food and beverage products and packaging including glass jars, plastic bottles, and cardboard boxes. While Domino’s V-Series range of thermal transfer overprinters are ideal for printing on flexible film packaging, laminated cardboard, and stand up pouches.

For some other food and beverage applications, a non-ink-based batch coder may present the best solution. For example, in the beverage sector, printing batch codes on the bottom of beer cans, wine bottles, and water bottles will require a system capable of printing on foil seals, PET, and glass. Such a solution can be found in Domino Printing’s range of durable D-Series CO2 lasers and F-Series fibre lasers – high-speed, harsh environment laser marking machines capable of printing codes onto a wide range of items and materials. This includes glass, plastic, foil, and metal.

Pharmaceutical

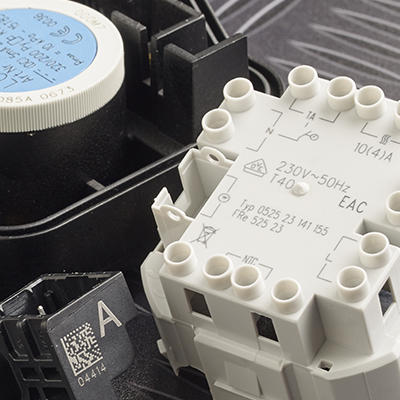

Batch code printers are critical for the pharmaceutical industry, where manufacturing dates, best before dates, anti-counterfeit Data Matrix codes, and regional legislative serialisation codes are often required by law.

Adding codes to pharmaceutical products is vital for making sure that drugs and medical devices are correctly monitored, and not abused by patients, those within the medical industry, or increasingly, criminal organisations.

Domino Printing’s Gx-Series thermal inkjet range of printers are non-contact ink coding machines that can achieve high-resolution printing, at very fast speeds (up to 300m a minute). These are ideal for the mass coding of drug and medical devices complex codes and messages to ensure compliance with regional and global legislation.

How much does it cost?

The cost of a batch coding system will vary greatly depending on an individual factory set up, the type of technology required, the number of machines, and the number of products that need coding. Ultimately there is a balance to be struck between the number of codes needed, the initial set up cost, and the cost of running a machine over time.

Ask the experts

Domino Printing provides a large range of batch coding machines for a variety of uses and sectors. You can view our full range here.

If you are looking for a batch coding machine, Domino has a solution for you. With options available for TTO, CIJ, TIJ, and laser coding, you are sure to find your ideal solution within the Domino range. All of our printers are available with QuickDesign coding automation software, allowing you to integrate your batch coding machine into existing systems, and fully automate the batch coding process.

Please get in touch to discuss your individual requirements with one of our experts, who will guide you through the selection process, to ensure that you find the perfect solution to your batch coding requirements.