Overview

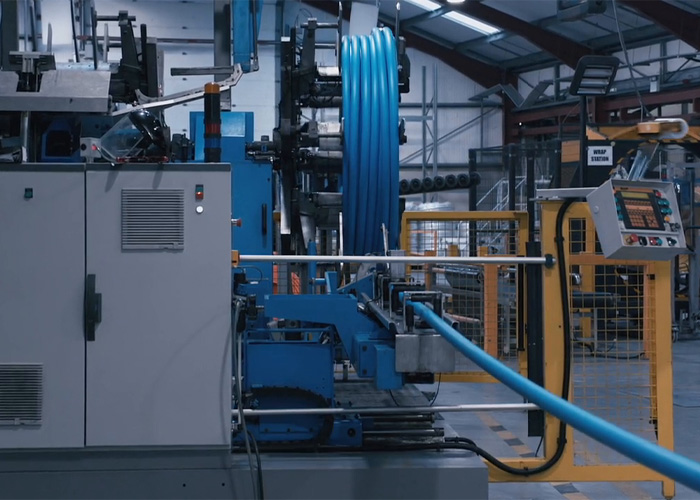

Pipelife in Cork, Ireland is a leading international manufacturer and provider of plastic piping systems. Specialising in the extrusion of polyethylene (PE) pipes, Pipelife offers industry leading products for the heating & plumbing, water pressure, electricity, cable ducting, gas, and agricultural sectors.

Fast Facts

- Pipelife is a leading supplier of piping system solutions with over 50 years of manufacturing experience and are based in 27 countries.

- Differing range of Polyethylene pipes of varying strengths.

- 740.000 km pipes installed in 2019.

- 36 new Ax350i continuous inkjet printer have been installed 9 printers are running with a yellow ink, 3 printers are using blue inks and 24 printers are running with a black ink.

Project background

Pipelife needed a solution that would guarantee simple handling, easy integration on existing lines and high-resolution printing especially at high speeds.

Pipelife had for many years experienced a good relationship with our competitors and the plant in Cork was an extensive competitor site. After many months of samplings, demos, trials and discussions, Codico managed to win the Pipelife business for Domino and received the first order.

Their chosen solution needed to handle the different production speeds being run and to deliver a high-quality print to always guarantee traceability.

Domino’s Ax350i represents a solution of high-speed printing with multi-line codes, and Codico successfully upgraded Pipelife’s extrusion lines with 36 Ax350i printers.

Dean Robins, Project Manager highlighted: “On our products, we have to have a legible, smudge-free, quality print at all times”. Essential in fulfilling their quality standards and important customer promise.

Coding requirements for pipes

Pipes are versatile and therefore must meet a wide variety of requirements. As well as national and international quality standards, the mechanical loads must be considered too.

Pressure and gas pipes, for example, must withstand particularly heavy loads, hot water pipes must be highly resilient and temperature safe. Water supply systems needs to be free of heavy metals and toxic chemicals.

This variety of properties require different materials and have different challenges to print on. Pipelife uses LDPE (Low Density Polyethylene), HDPE (High Density Polyethylene), PEX (Polyethylene Cross Linked), PERT (Polyethylene Raised Temperature), and PB (Polybutylene).

How did Domino and Codico select the appropriate solution?

Domino’s Distributor Codico, have determined that CIJ technology would be the most appropriate for these coding applications. CIJ technology is fast, durable, easy to operate, simple to install, and is extremely versatile: it can print on virtually any surface. With CIJ printing the requested simplicity was given.

Each material behaves differently depending on its composition.

Over 30 Domino CIJ inks in different colours are successfully established in industrial applications.

During initial testing of various inks in the Domino sample lab, we tested everything from rub test through the haul-off, to coiling testing, dry times, scratch resistance, sharpness of print, longevity in standard weathering conditions (rain / sun etc). The most challenging test was the ultimate test through the steamers. Pipelife “cures” their pipes at 85° for minimum of 8 hours, in the praxis for longer because of change in shifts etc.