Domino Amjet North America's engineers are proud to offer environmentally-friendly thermal transfer overprinting solutions without sacrificing print quality. Our innovative roster of TTO printers don't require compressed air for ink, Domino can bring manufacturers the grand slam of efficiency - offering environmental, cost and operational efficiency - all in one TTO.

No compressed air for a TTO? No problem.

Across the majority of industrial printer manufacturers, TTO printers require compressed air to operate. Not so for our Vx150i and V230i units.

That one important attribute means that manufacturers across several industries can expect environmental, cost and operational savings - without sacrificing any print quality for their products.

Of course, the lack of air compressors is just the start of what makes the V-Series such a massive hit in the thermal transfer printer space.

There’s a quick summary below. But first let's consider if you should even have this type of technology in mind for deployment in your factory.

Is a Thermal Printer right for your business?

Why you might consider thermal transfer printing technology is its flexibility. You can use it for a range of applications, just as we recommend it for deployment for manufacturing plants in a number of different industries.

For example, Domino’s V-Series can print variable data, barcodes and images at 300dpi onto multiple substrates commonly used in the food, pharmaceutical and industrial sectors.

While these products will make their way to everything from your home's kitchen to your medicine cabinet, and maybe even onto the wiring of said kitchen's refrigerator, there are plenty of ways to deploy a Domino V-Series into your operation - and ultimately, you'll be able to trust it in each and every one of them.

>> 6 reasons every snack manufacturer needs TTO technology

Environmental savings

As we mentioned above, the V-Series units are among a small handful of industrial TTO printers that don’t use compressed air.

That’s a huge point - and we're not just being hyperbolic because the V-Series is ours.

Compressed air has a significant environmental impact thanks to emissions output. To compound the problem, many compressed air systems are prone to leaks - making them even less efficient.

Instead of compressed air, the Domino V-Series uses printhead pressure and movement controlled by electronic stepper motors. As a result, there’s zero need for environmentally-costly compressed air. Plus, as an additional benefit, our electronic stepper system requires less power than direct ribbon drive systems with pneumatic printhead actuation.

In short: a cleaner mode of operation in terms of emissions - and one that also requires less electrical power.

Economic savings for your business

Of course, what’s good for Mother Nature is also good for your bottom line. Energy savings mean economic savings. But this is about more than utility bills. Compressed air is one of the most expensive services in a production plant. If you can reduce its use wherever possible, there’s the potential for significant cost savings. Especially as compressed air systems also come with sizeable installation, repair and maintenance costs.

Operational savings

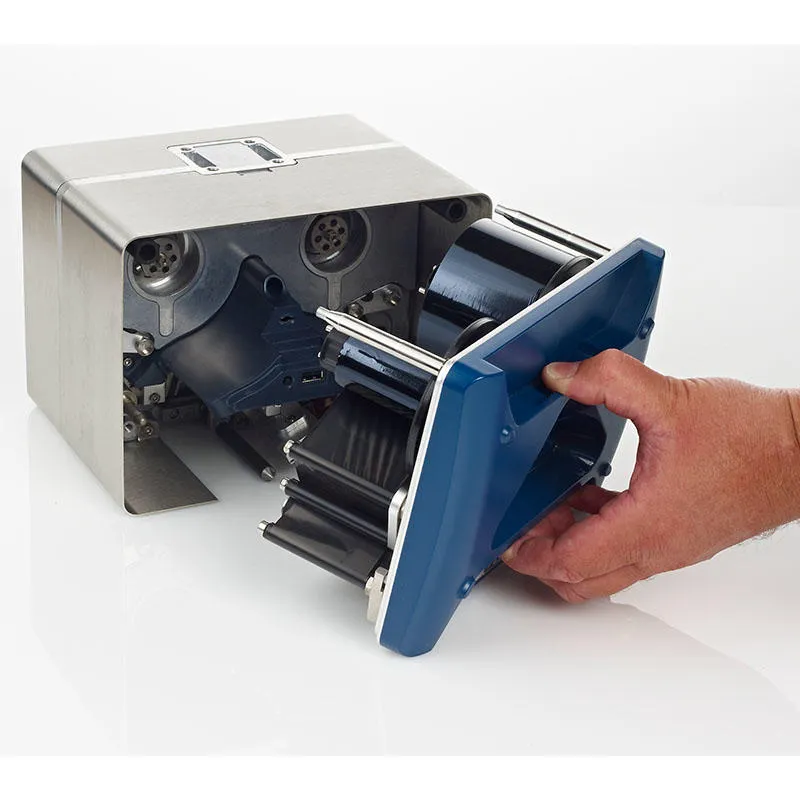

As we mentioned above, compressed air supplies have a nasty habit of leaking. These leaks can cost up to 30% of annual printer consumables usage, which has a major impact on operational efficiency. That’s not all. In factories where access to the compressed air supply is in high demand, there are obvious benefits to systems that don’t add to that demand. Also, due to the fact that V-Series units are small, portable and require only an electrical supply for operation, V-Series printers are easy to retro-fit onto production lines where space is already at a premium and flexibility is crucial.

Better results

Of course, all of the economic, environmental and operational savings won't count for anything if the code quality isn't up to par.

How does our TTO measure up quality-wise? Well, thank you for asking, dear rhetorical reader.

Our engineers set out to create consistency across all codes - all while achieving our goal of less waste and easier setup. Another important point is that the lack of compressed air means print quality is consistent because the printer isn’t subject to fluctuations in air pressure. When we say 300dpi, we mean it with each and every code - not 300 dpi when conditions are juuuuust right and you're air compressor is sent from the Heavens on a golden cloud.

The electrical printhead means you can enjoy optimal setup at the touch of a button. No tools or shims necessary.

And now consistent quality doesn’t have to cost the Earth.

Find out more about the V-Series at domino-printing.com.

How does a thermal transfer printer work?

Let's start with the basics here. A Thermal Transfer Overprinter, like our entire lineup of V-Series TTOs is, at its most basic level, a Thermal Transfer Printer. That type of printer works when a heated thermal element melts a wax-based ink onto a substrate.

Due to the makeup of the ink, what makes TTO an excellent solution is how fluid and water resistant and is also abrasion resistant compared to traditional inks thanks to its heat-based application.

Thanks to this tough application, that's why thermal transfer is one of the most widely used industrial printing applications, and used from everything like high end date, QR and bar coding like our V-Series to the most basic label printers for shipping and labeling in stores.